- Joined

- Nov 16, 2012

- Messages

- 5,596

Hi Folks,

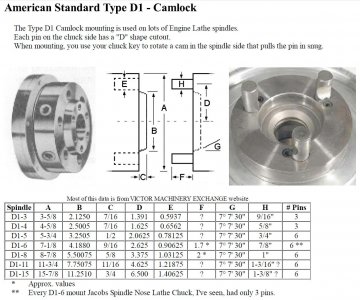

By popular demand, I'll post some information about D1-4 spindle and chuck dimensions which I hope to include various techniques to measure things. We'll need to do all kinds of measuring, use granite plates etc. This will take a few days to get through but by the end, it will show a technique I've been using to true-up chucks so they mount perfectly and repeatably. This is only loosely structured as I'm really low on time these days. -Have 2 paying jobs in the shop and the 9-5 day job is getting in the way too... Hang in there. I promise this will pertain to Metrology using a live example.

Note: I'm not a professional machinist -just a lifelong shop rat that loves this stuff. If along the line, I use incorrect terminology or improvements/suggestions are in order, shout it out.

Regards

Ray

Part 1:

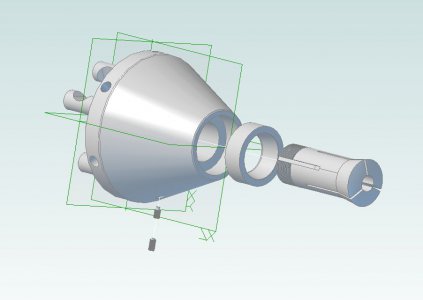

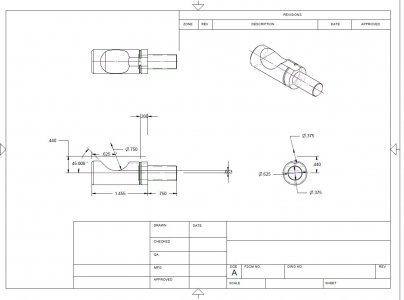

When I recently mounted my old collet chuck on a new D1-4 back, I discovered the back was pretty crude. It would not mount repeatably and closing the locking lugs was next to impossible. Please see the first picture that shows the problem in exaggerated form. There should be no light coming between backplate and spindle face. BTW: I'm demonstrating on a back that's already been properly fitted so, this will show a "sunny-day" scenario of what's going on.

Also, take a look at the PDF. If you have Adobe Reader, you can click the image and rotate it with the mouse. Please note, the faces of the back and spindle nose must contact at the same time the tapered part of the spindle nose contacts the inner race taper of the back. This is a tough geometry to get right -but if you do, your chucks will mount perfectly -every time.

Part 2 coming in the next thread...

View attachment 95507

View attachment 95507

By popular demand, I'll post some information about D1-4 spindle and chuck dimensions which I hope to include various techniques to measure things. We'll need to do all kinds of measuring, use granite plates etc. This will take a few days to get through but by the end, it will show a technique I've been using to true-up chucks so they mount perfectly and repeatably. This is only loosely structured as I'm really low on time these days. -Have 2 paying jobs in the shop and the 9-5 day job is getting in the way too... Hang in there. I promise this will pertain to Metrology using a live example.

Note: I'm not a professional machinist -just a lifelong shop rat that loves this stuff. If along the line, I use incorrect terminology or improvements/suggestions are in order, shout it out.

Regards

Ray

Part 1:

When I recently mounted my old collet chuck on a new D1-4 back, I discovered the back was pretty crude. It would not mount repeatably and closing the locking lugs was next to impossible. Please see the first picture that shows the problem in exaggerated form. There should be no light coming between backplate and spindle face. BTW: I'm demonstrating on a back that's already been properly fitted so, this will show a "sunny-day" scenario of what's going on.

Also, take a look at the PDF. If you have Adobe Reader, you can click the image and rotate it with the mouse. Please note, the faces of the back and spindle nose must contact at the same time the tapered part of the spindle nose contacts the inner race taper of the back. This is a tough geometry to get right -but if you do, your chucks will mount perfectly -every time.

Part 2 coming in the next thread...

View attachment 95507

View attachment 95507Attachments

Last edited: