- Joined

- Dec 22, 2011

- Messages

- 310

To cut the teeth on the gear blank, I decided to try out these indexing centers that came with my mill when I bought it. I don't think they've been used in many years because they were seized up and missing a couple of little parts. I got them freed up and working though:

The indexer is pretty simple. You simply mount a gear on the end and use it to index the teeth. I am making a 16 pitch, 14-tooth gear, so I mounted a 56-tooth gear on the indexer and used every fourth tooth when cutting the teeth in the blank. I bought a bunch of used gear cutters on ebay awhile back and as luck would have it, I had the cutter I needed on hand:

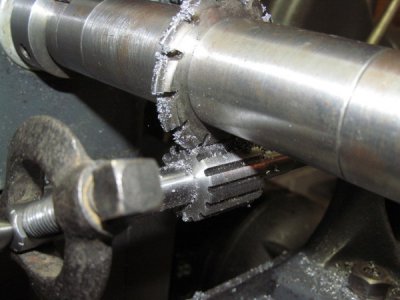

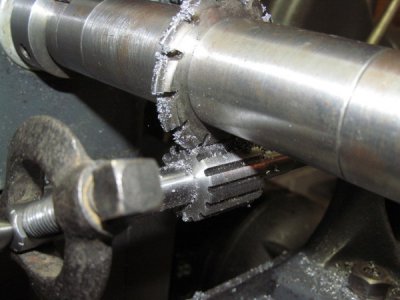

My little mill didn't seem to like it when I tried to cut the first tooth at full depth. So I backed off and cut the teeth in stages:

For my first attempt at gear cutting, I was pretty happy with how it turned out. I still need to cross drill the gear and shaft and ream the hole for a taper pin, but here it is alongside the original:

The indexer is pretty simple. You simply mount a gear on the end and use it to index the teeth. I am making a 16 pitch, 14-tooth gear, so I mounted a 56-tooth gear on the indexer and used every fourth tooth when cutting the teeth in the blank. I bought a bunch of used gear cutters on ebay awhile back and as luck would have it, I had the cutter I needed on hand:

My little mill didn't seem to like it when I tried to cut the first tooth at full depth. So I backed off and cut the teeth in stages:

For my first attempt at gear cutting, I was pretty happy with how it turned out. I still need to cross drill the gear and shaft and ream the hole for a taper pin, but here it is alongside the original: