- Joined

- Aug 22, 2017

- Messages

- 157

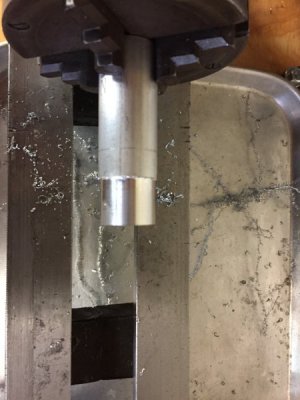

Alright, I ordered a bushing but I've also ordered some material that probably a bit more appropriate for my machine.

I think before I take anything apart I'll give the 6061 and the 12L14 a go with and with out the tail stock supporting the work. If I can get decent results I'll probably just leave it as is and make some chips.

If it still leaves a bad finish I'll install the split bushing and go from there.

If all that fails...

https://maine.craigslist.org/bar/d/10-machine-lathe-atlas/6324620633.html

(I'm only somewhat joking...no idea on it's condition but this is the size machine I was looking for).

K

I think before I take anything apart I'll give the 6061 and the 12L14 a go with and with out the tail stock supporting the work. If I can get decent results I'll probably just leave it as is and make some chips.

If it still leaves a bad finish I'll install the split bushing and go from there.

If all that fails...

https://maine.craigslist.org/bar/d/10-machine-lathe-atlas/6324620633.html

(I'm only somewhat joking...no idea on it's condition but this is the size machine I was looking for).

K