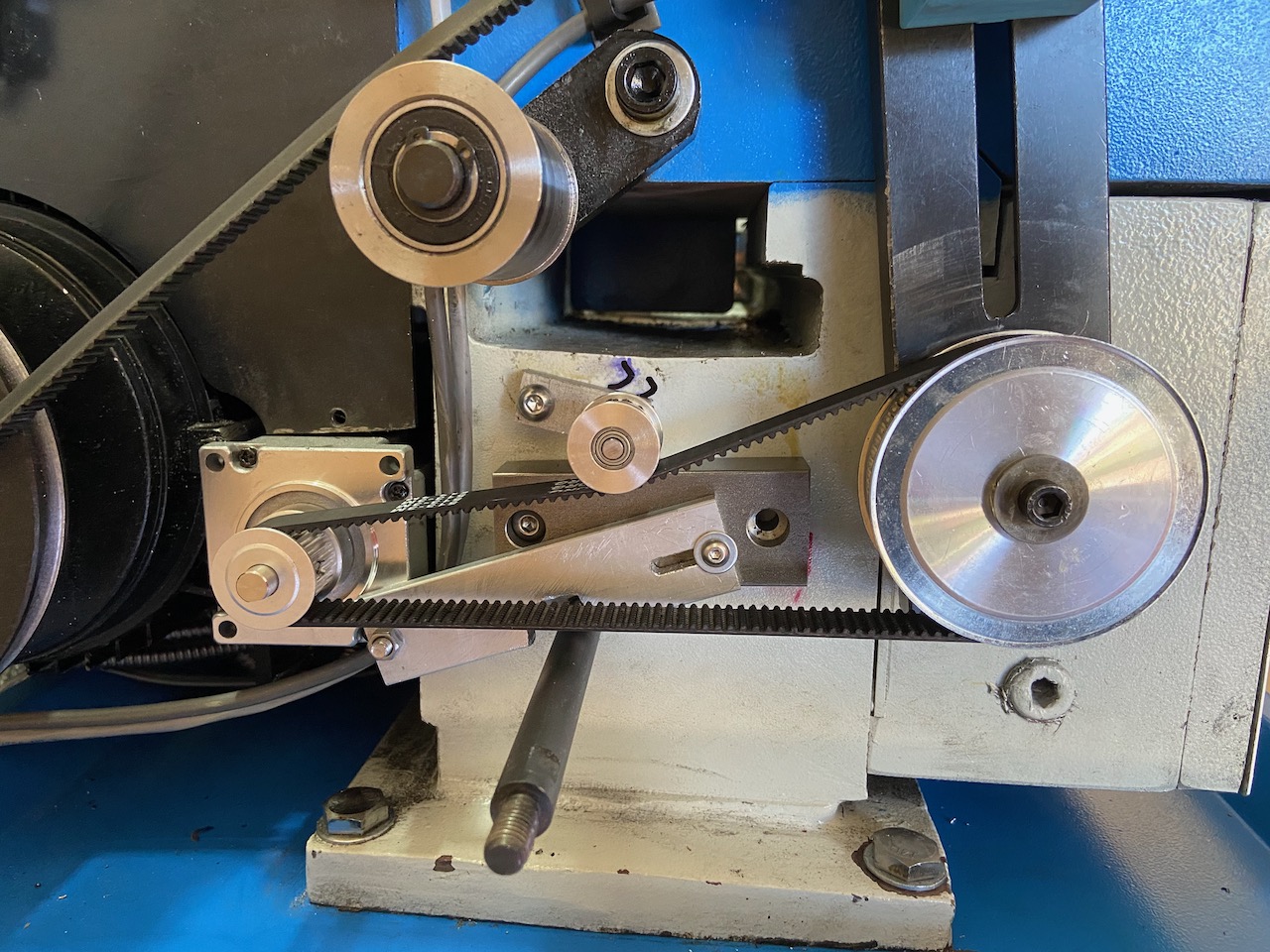

Here's my "final" setup. It looks flimsy with all these ugly-looking brackets but in fact it is very rigid, the motor is very secure and doesn't move at all. So far so good, but of course, I'm planning to design and make a proper mounting bracket, and probably make an encoder mount out of metal too, instead of the 3d-printed one.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clough42 ELS on PM1130V

- Thread starter javaduke

- Start date

I'm planning to go down this path in the near future. I have the same lathe, an 1130v (and mine came about 6 months after yours, so roughly the same vintage).

I'm having trouble seeing how that servo fits into that space. It doesn't look 57mm wide. I guess I need to print a mock-up to see if I can wiggle it into place. Did you need to modify anything else to get it to fit?

Are the connections on the top or the bottom of the servo in your setup? And how is it bolted in place?

RR

I'm having trouble seeing how that servo fits into that space. It doesn't look 57mm wide. I guess I need to print a mock-up to see if I can wiggle it into place. Did you need to modify anything else to get it to fit?

Are the connections on the top or the bottom of the servo in your setup? And how is it bolted in place?

RR

To be honest, I did have to file down the casting of the lathe motor just a little bit, I did it in situ with a mill bastard file. The servo fits in that space really snugly, there's even no need to bolt it down, but I did it anyway, just with this single makeshift bracket. Everything is very tight there and doesn't move at all. Of course, eventually I will make a proper mounting bracket and get rid of all this abomination, but for now it seems to work ok.

The connectors are at the top of the servo and I rerouted them back to the electronics box.

If you ever visit the Phoenix area, feel free to stop by and I will show you my setup

The connectors are at the top of the servo and I rerouted them back to the electronics box.

If you ever visit the Phoenix area, feel free to stop by and I will show you my setup

- Joined

- Jun 22, 2023

- Messages

- 728

im following along and congrats on a great adaptation, i was wondering if you could have fabricated a riser to mount the lathe bed on moving the lathe up 2" and underslung the motor under the gearbox?Here's my "final" setup. It looks flimsy with all these ugly-looking brackets but in fact it is very rigid, the motor is very secure and doesn't move at all. So far so good, but of course, I'm planning to design and make a proper mounting bracket, and probably make an encoder mount out of metal too, instead of the 3d-printed one.

View attachment 461993

Thanks for the info. And the offer. I doubt I'll be close to Phoenix though.

You had a great advantage (along with the problem ) of already having the servo in hand when you switched locations. I think I will go ahead and 3d print a mock-up part and see how hard it is to fit.

) of already having the servo in hand when you switched locations. I think I will go ahead and 3d print a mock-up part and see how hard it is to fit.

However.....I have another couple of questions.

1) Did you need to file a bit off one of the heat fins on the spindle motor? Seems like it will get difficult to file at the full depth of the servo. A Dremel with a sanding disk might work if it's needed.

2) How did you slide the "hump" on top of the servo into the channel? I'm now thinking that I should just cut the black plate cover about 3/4" higher than it is after filing. That would let the hump slide right in. That screw hole isn't needed any longer. This picture shows a very wavy line about where I'd cut it:

You had a great advantage (along with the problem

I did the 3d print and set to work with my file. the bottom of the black cover plate clearly needed to be reduced. I also filed a bit of the motor mount at the one of three bolts that was close (not sure that was needed). I only made the 3d print about 65 mm deep to save a bit of time. As you can see, it "kinda" fits now.To be honest, I did have to file down the casting of the lathe motor just a little bit, I did it in situ with a mill bastard file. The servo fits in that space really snugly, there's even no need to bolt it down, but I did it anyway, just with this single makeshift bracket. Everything is very tight there and doesn't move at all. Of course, eventually I will make a proper mounting bracket and get rid of all this abomination, but for now it seems to work ok.

The connectors are at the top of the servo and I rerouted them back to the electronics box.

If you ever visit the Phoenix area, feel free to stop by and I will show you my setup

However.....I have another couple of questions.

1) Did you need to file a bit off one of the heat fins on the spindle motor? Seems like it will get difficult to file at the full depth of the servo. A Dremel with a sanding disk might work if it's needed.

2) How did you slide the "hump" on top of the servo into the channel? I'm now thinking that I should just cut the black plate cover about 3/4" higher than it is after filing. That would let the hump slide right in. That screw hole isn't needed any longer. This picture shows a very wavy line about where I'd cut it:

I think I might have a slightly improved location for mounting the servo on the 1130v. Javaduke put his into place snugly, but I worry that having contact between the servo and other parts of the lathe might risk rubbing over the long term. And I'm concerned that the fit was so close that it might work on some lathes with some servos...but not in every case.

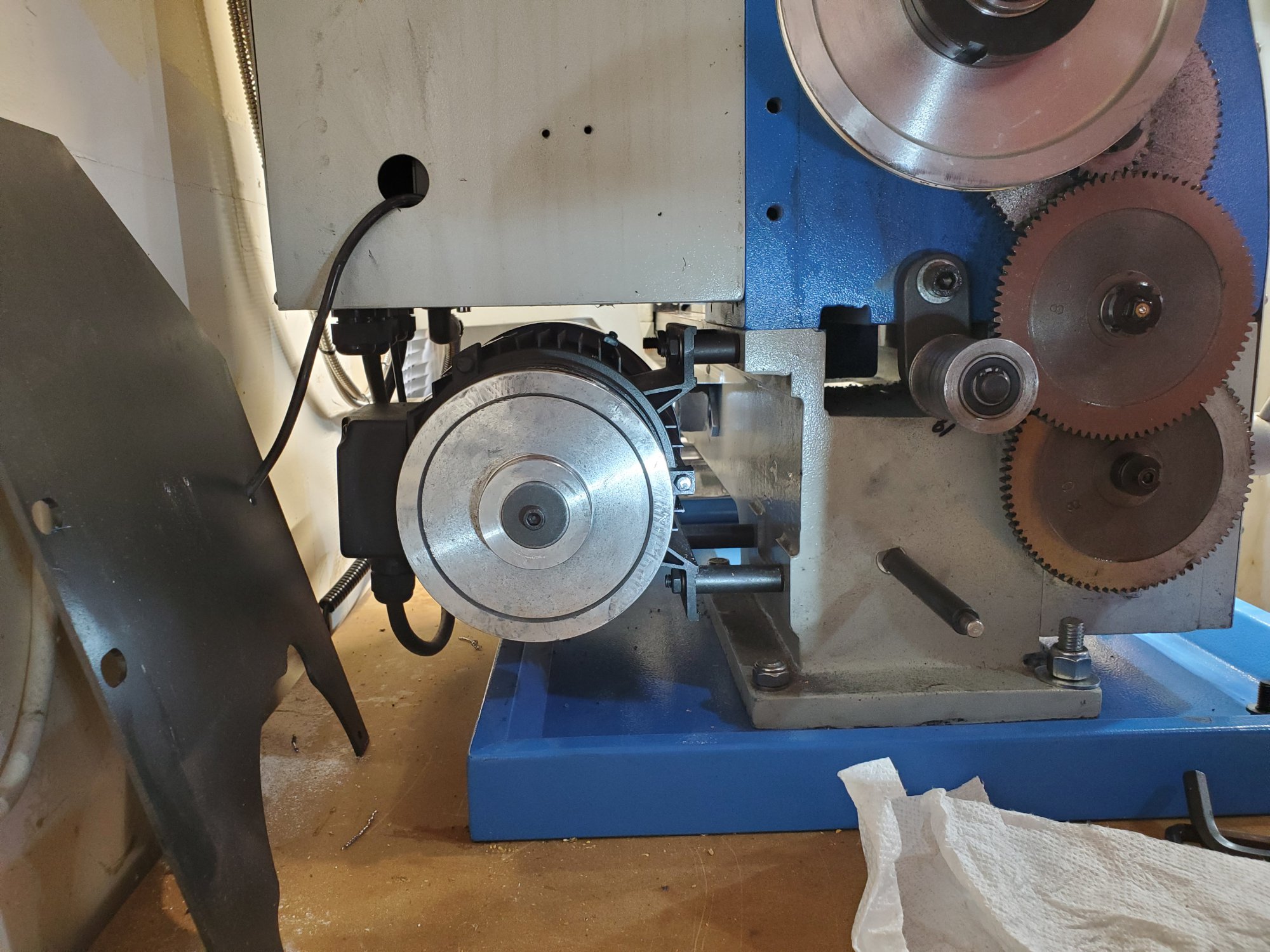

So I finally decided to open things up so I could see the entire area. I already had the lower motor cover plate off. I removed the upper motor cover plate. Just a few screws. I also removed the backsplash (which covers the back side of the motor). At this point, I could see this:

The obvious location for the servo is between the motor and the large lathe bed casting. But, it's just a tiny bit too narrow for an easy fit. It's hard to measure exactly, but I think the space is about 53-54mm wide while the servo is spec'ed at 56 wide. Javduke got his servo in place with some file work and it only fits when it's tilted a few degrees.

My though now is to move the motor away from the lathe bed casting. Just a little bit. The motor is mounted with four (4) M8 bolts. Those bolts are on the end of the black standoff cylinders and are clearly visible between the motor and the lathe bed casting. There's a few options:

1) A washer/spacer can be inserted between each standoff and the motor mounts. The two mounting bolts farthest from the camera are quite long (I see ~10mm of visible thread on the top one). The two bolts close to the camera have at least two threads visible, so my estimate is that a 2.5 mm spacer could be added. It might also be possible to use a thinner washer over the slot on the side toward the motor, buying perhaps another .5mm.

2) Any or all of the standoffs could be replaced with slightly longer versions for more distance than the washers would provide.

Bottom line is that it's possible to move the motor for more space and it's not that difficult to do so.

If the motor moves backwards, the v-belt from the motor to the spindle will be tighter. Mine is already annoyingly tight. However, the motor mount pieces are slotted. And at least on my lathe, the motor is currently down at the bottom of the slots. So it can be moved higher, as needed, to allow the belt distance to be adjusted.

So I finally decided to open things up so I could see the entire area. I already had the lower motor cover plate off. I removed the upper motor cover plate. Just a few screws. I also removed the backsplash (which covers the back side of the motor). At this point, I could see this:

The obvious location for the servo is between the motor and the large lathe bed casting. But, it's just a tiny bit too narrow for an easy fit. It's hard to measure exactly, but I think the space is about 53-54mm wide while the servo is spec'ed at 56 wide. Javduke got his servo in place with some file work and it only fits when it's tilted a few degrees.

My though now is to move the motor away from the lathe bed casting. Just a little bit. The motor is mounted with four (4) M8 bolts. Those bolts are on the end of the black standoff cylinders and are clearly visible between the motor and the lathe bed casting. There's a few options:

1) A washer/spacer can be inserted between each standoff and the motor mounts. The two mounting bolts farthest from the camera are quite long (I see ~10mm of visible thread on the top one). The two bolts close to the camera have at least two threads visible, so my estimate is that a 2.5 mm spacer could be added. It might also be possible to use a thinner washer over the slot on the side toward the motor, buying perhaps another .5mm.

2) Any or all of the standoffs could be replaced with slightly longer versions for more distance than the washers would provide.

Bottom line is that it's possible to move the motor for more space and it's not that difficult to do so.

If the motor moves backwards, the v-belt from the motor to the spindle will be tighter. Mine is already annoyingly tight. However, the motor mount pieces are slotted. And at least on my lathe, the motor is currently down at the bottom of the slots. So it can be moved higher, as needed, to allow the belt distance to be adjusted.

I moved the motor last night. Easier than expected. The standoffs that support the motor are 8 mm studs surrounded by a spacer. When I discovered that, I was concerned that the studs might be difficult to adjust or remove. But it turns out that the studs can be removed by using your fingers....they aren't lock-tighted or stuck in place at all. And they threaded into the lathe casting about 20 mm deep, so they can be adjusted out a bit with no problem.

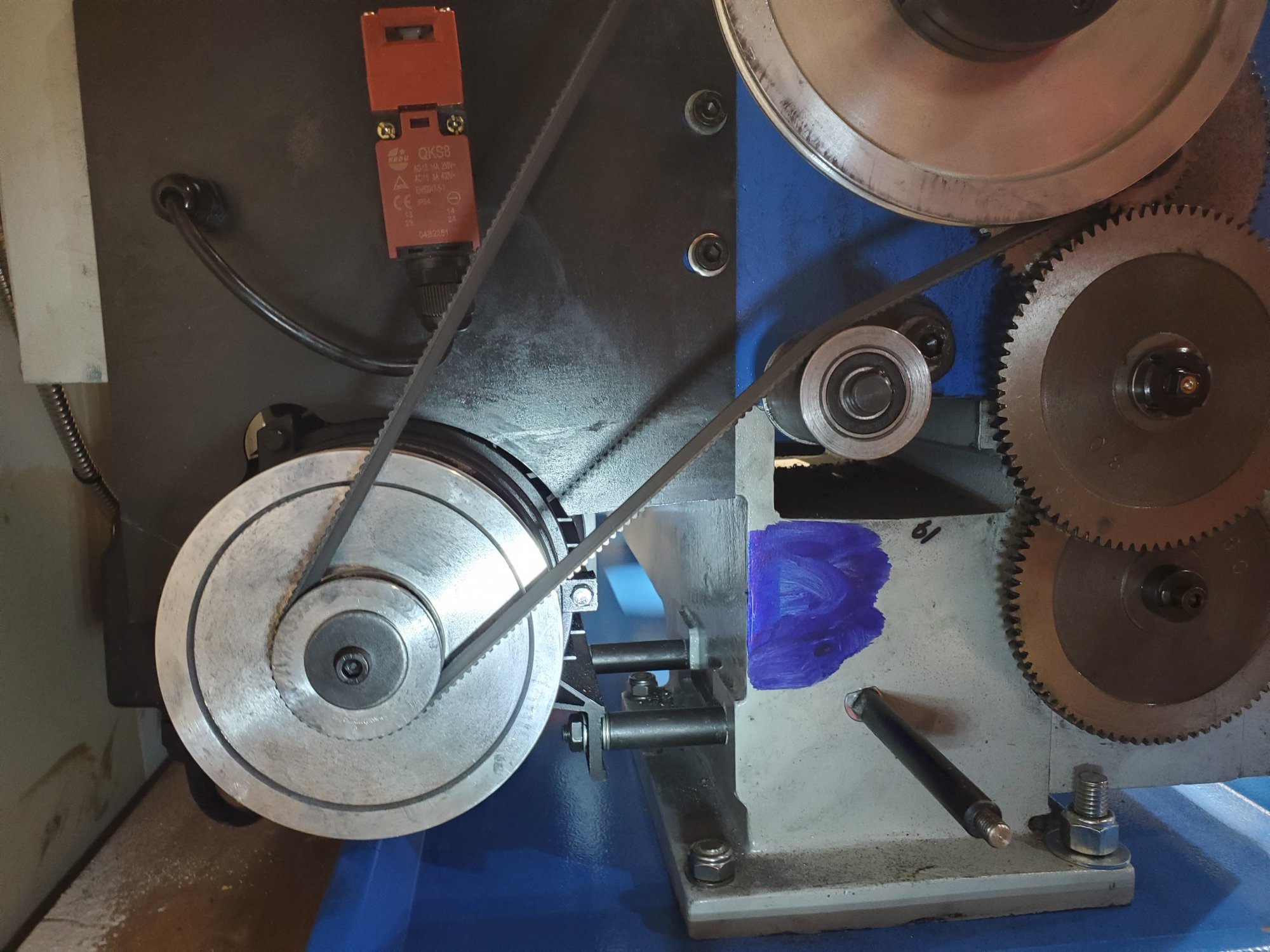

I adjusted the shortest 3 of the 4 out 4 or 5mm. And then put three washers in place to extend the effective length of the spacers by 4.5 mm. A NEMA 23 will now fit easily. I also trimmed the top cover plate about an inch to allow the servo electronics hump to slid in w/o removing the plate. Plate and belt all still fit properly. The widened/opened area now looks like this (the servo fits to the left of the blued area on the casting). The 3 washers on the spacer are visible for the lower stud closest to the camera.

I adjusted the shortest 3 of the 4 out 4 or 5mm. And then put three washers in place to extend the effective length of the spacers by 4.5 mm. A NEMA 23 will now fit easily. I also trimmed the top cover plate about an inch to allow the servo electronics hump to slid in w/o removing the plate. Plate and belt all still fit properly. The widened/opened area now looks like this (the servo fits to the left of the blued area on the casting). The 3 washers on the spacer are visible for the lower stud closest to the camera.

- I finished my ELS install a week or two back. Here's a picture.

In adding the picture, I see that I still need to do a anchor for my cable to the controller/display (so not quite complete). But, it's in and it works. I ran for a bit with the original firmware from Clough42. But, I've already switched over to another branch of the code. The version I'm running now lets you

- show the angle of the spindle (in place of showing RPM).

- It allows entering "any" pitch for a thread, rather than a select few.

- And, it allows a "Thread to Shoulder" function that's pretty slick. Once you set the shoulder (stopping) position and the beginning position, it moves the carriage to cut up to the shoulder, then stops the carriage. At this point, you need to stop the spindle and then retract the cross slide. The firmware then moves the carriage back to the beginning location (even though the spindle isn't turning) and when there, you wet the cross slide (and or compound) for the next cut. Turn on the spindle and it cuts the next pass.

https://github.com/kwackers/electronic-leadscrew

I'll also note that the correct v-belt to go direct from the servo motor to the gearbox input shaft for my PM-1130v is a belt that SDP-SI doesn't carry. I started with their 575mm long belt and it is definitely too long. From Vbeltmart.com, I ordered a 570mm and a 565mm length. The 565mm is too short, but the 570mm is perfect.

Last edited: