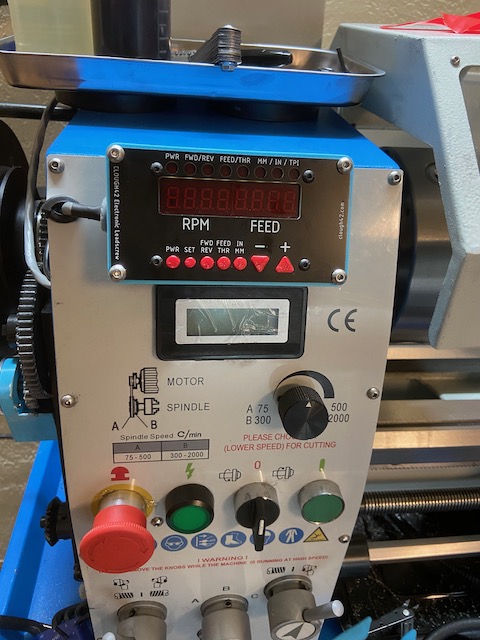

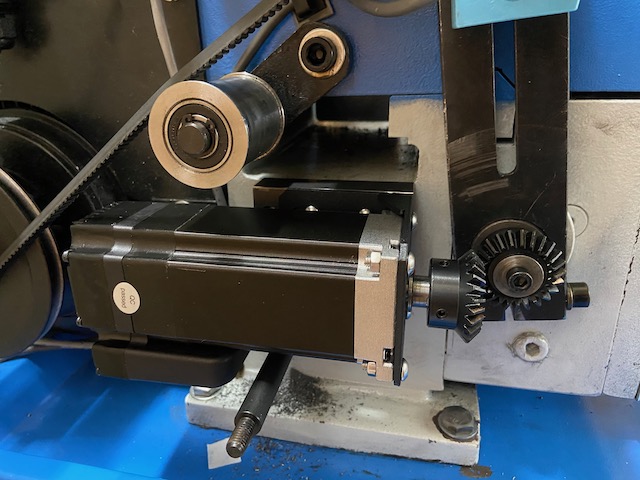

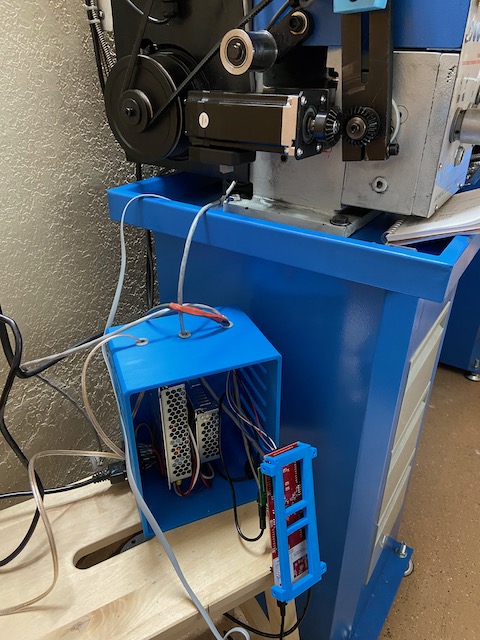

I've been lurking here for quite a while but decided to make a post (and ask for a suggestion too). Just a month ago I got my PM1130V lathe and decided to build an ELS for it, because the space in my garage is tight and changing gears each time would be tricky. Here are some pictures of my setup:

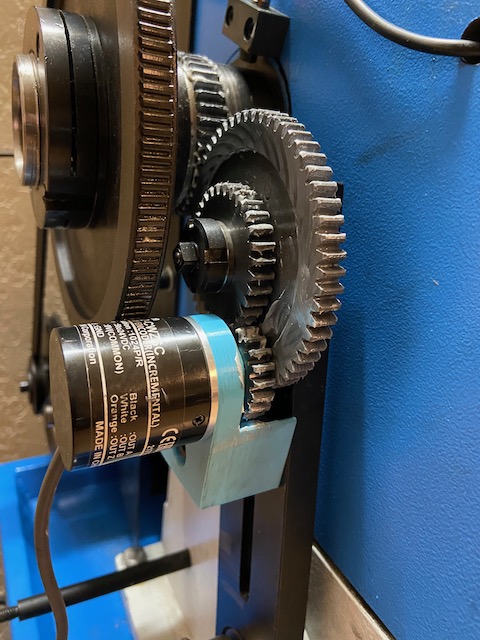

Oddly enough, everything worked as it should right away - well, at least, the electronics part. The issue I'm having right now is that the gear ratio from the servo to the shaft is 1:1 - which is definitely not enough. Since the machine also has an internal gearbox, my plan is to have 1:3 ratio to the shaft and leave the internal gearbox at the C setting which will give me a total of 1:6 reduction. The question is where can I buy the correct gear? It has to be metric, 14mm bore, 5mm keyway, module 1.5 and 60 tooth count. My google fu has failed me again, I cannot find anything like this, at least not for a reasonable price.

Oddly enough, everything worked as it should right away - well, at least, the electronics part. The issue I'm having right now is that the gear ratio from the servo to the shaft is 1:1 - which is definitely not enough. Since the machine also has an internal gearbox, my plan is to have 1:3 ratio to the shaft and leave the internal gearbox at the C setting which will give me a total of 1:6 reduction. The question is where can I buy the correct gear? It has to be metric, 14mm bore, 5mm keyway, module 1.5 and 60 tooth count. My google fu has failed me again, I cannot find anything like this, at least not for a reasonable price.