So if your reading is .002" off at 8", that could be a 1.28 degree tilt, first thing I would check are your scales and the holder. At 8" the height difference would be .1789",maybe not so noticeable?

Hi guys

Ok you guys are way way over my head here!

I went back and read my original post and think I left some things out, This is how I checked it yesterday.

I mounted a indicator in the spindle and laid a 123 block on the table and squared it up with indicator. I then clamped it down and zeroed my indicator and the DRO.

I then ran table in the X axis down 6" and checked with the indicator and compared to the DRO I was neg maybe .0008

I then went 8" and was Pos .0014.

I take it, it was good to have it read back and forth as this could be rounding issues and other things that a old mill could interduce into the readings.

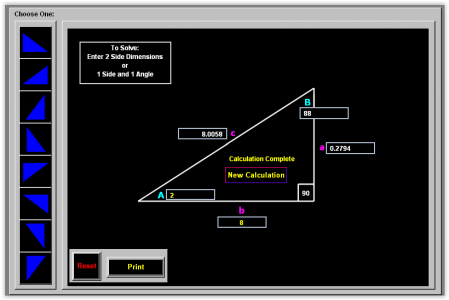

I am brand new to machining and have a real hard time understanding instructions that are written, I do much better with visual aids.

So tell me does the tilt of the blocks still play into it? I am thinking at this point what I am getting now is pretty good for a old mill and old man.

I really do appreciate all the time you guys spend help me and everyone else on this site.

One thing I still have not been able to find was how to get into linear compensation on the DRO. Not that I think I need to change it anyways.

Thank you again