- Joined

- Jul 17, 2020

- Messages

- 323

I've had the Horrible Freight mini lathe for a few weeks now, and the only place I can currently put it is on a wooden workbench that's older than dirt. No way to level the lathe, and it was really bad, like a 0.015" diameter change over 6" in a piece without tailstock support. I decided to cast this 2" thick slab of concrete both to level the bed, and to give the machine more mass in general. I'm going to be pretty verbose in this so I can either get criticism for how to do it better, or so other people can do this too.

I made a mold out of melamine countertop and put some 1/4-20 bolts in the right spots to act as studs for the lathe feet. I didn't feel like finding a hammer drill for the concrete and getting proper anchor bolts, and it's only a mini lathe, so this is fine. All edges were caulked.

I put in two layers of metal scrim for reinforcement. The concrete isn't any kind of fancy countertop grade, just the regular fiber crack resistant stuff. Ignore the bucket label, it was empty and just used for concrete mixing. Nearly set the drill on fire haha.

It looks pretty wet, but I really didn't over water it, it's just smoothed out.

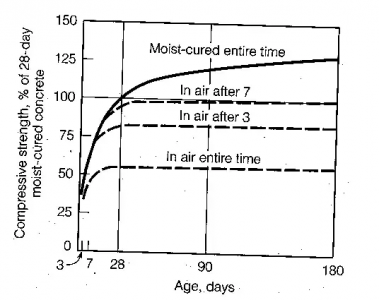

I thought 36 hours was long enough to take it out of the mold. I was wrong. The edges got chipped, but nothing major broke. It should have been more like 72 hours. I waited a few more days before mounting the lathe.

I have some level vials down to 20 seconds, but I only have a base made for a 90 second vial. After a quick check with it I went to checking with a 6" long 3/4" piece of 12L14, again unsupported by the tailstock. It took me about an hour to get it down to a 0.0005" difference in diameter end-to-end, which is way more than good enough for now. Maybe once the concrete is actually done curing in a few months I'll get it even better.

Now with the increases rigidity I'll be able to make use of a 1/2hp 3-phase Baldor motor I have coming. The brushed DC motor that came with this is wimpy as crap, and can't quite make a 0.01" pass in 1" 12L14 without stalling, on low gear. Boy do 7.5 thou passes take forever when you've got a lot of material to come off. I can also always stick a 2hp 3ph Baldor I have laying around on it if I really want to blow the machine up from a crash lol.

I made a mold out of melamine countertop and put some 1/4-20 bolts in the right spots to act as studs for the lathe feet. I didn't feel like finding a hammer drill for the concrete and getting proper anchor bolts, and it's only a mini lathe, so this is fine. All edges were caulked.

I put in two layers of metal scrim for reinforcement. The concrete isn't any kind of fancy countertop grade, just the regular fiber crack resistant stuff. Ignore the bucket label, it was empty and just used for concrete mixing. Nearly set the drill on fire haha.

It looks pretty wet, but I really didn't over water it, it's just smoothed out.

I thought 36 hours was long enough to take it out of the mold. I was wrong. The edges got chipped, but nothing major broke. It should have been more like 72 hours. I waited a few more days before mounting the lathe.

I have some level vials down to 20 seconds, but I only have a base made for a 90 second vial. After a quick check with it I went to checking with a 6" long 3/4" piece of 12L14, again unsupported by the tailstock. It took me about an hour to get it down to a 0.0005" difference in diameter end-to-end, which is way more than good enough for now. Maybe once the concrete is actually done curing in a few months I'll get it even better.

Now with the increases rigidity I'll be able to make use of a 1/2hp 3-phase Baldor motor I have coming. The brushed DC motor that came with this is wimpy as crap, and can't quite make a 0.01" pass in 1" 12L14 without stalling, on low gear. Boy do 7.5 thou passes take forever when you've got a lot of material to come off. I can also always stick a 2hp 3ph Baldor I have laying around on it if I really want to blow the machine up from a crash lol.

Last edited: