- Joined

- Aug 29, 2019

- Messages

- 1,165

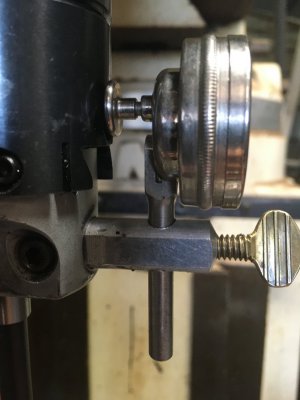

I got the bushing installed in the casting today with very little trouble. I took the advice of the Master's on the site and polished .001 off of the O/D of the bushing and froze it for an hour. Took some effort but not a big deal. I am satisfied it is as tight as it needs to be and will stay anchored when I finish bore the I/D of the bushing. The pictures show it after pressing (pulling) it into the casting. Also the method i used to pull it into the casting. The Old back plunge indicator allows me to hit the numbers I am targeting with little problem. Of course I remove the indicator and thumb screw before turning the mill on. The bushing looks to be slightly off center and that is because it is. I simply indicated the center line of the existing hole and it was bored off center from the factory. Hopefully the gears will mesh with no problem. I did mesh the gears before boring the casting. You can see the shaft has already been welded and re machined once already. It is only .738 O/D so a factory bronze bushing was just too loose to suit me. Handle was flopping and gears very sloppy mesh. As Josh Topper says "Do it right the first time" I could not sleep at night knowing I did a sloppy half a$$ job.

Attachments

-

IMG_3225.JPG252.5 KB · Views: 13

IMG_3225.JPG252.5 KB · Views: 13 -

IMG_3213.JPG199.8 KB · Views: 13

IMG_3213.JPG199.8 KB · Views: 13 -

IMG_3214.JPG263 KB · Views: 10

IMG_3214.JPG263 KB · Views: 10 -

IMG_3215.JPG215.7 KB · Views: 10

IMG_3215.JPG215.7 KB · Views: 10 -

IMG_3216.JPG238.2 KB · Views: 11

IMG_3216.JPG238.2 KB · Views: 11 -

IMG_3217.JPG196.5 KB · Views: 10

IMG_3217.JPG196.5 KB · Views: 10 -

IMG_3218.JPG195.6 KB · Views: 9

IMG_3218.JPG195.6 KB · Views: 9 -

IMG_3219.JPG174.7 KB · Views: 8

IMG_3219.JPG174.7 KB · Views: 8 -

IMG_3220.JPG177.5 KB · Views: 8

IMG_3220.JPG177.5 KB · Views: 8 -

IMG_3221.JPG179.5 KB · Views: 9

IMG_3221.JPG179.5 KB · Views: 9 -

IMG_3222.JPG187.4 KB · Views: 9

IMG_3222.JPG187.4 KB · Views: 9 -

IMG_3223.JPG187.6 KB · Views: 9

IMG_3223.JPG187.6 KB · Views: 9 -

IMG_3224.JPG204.3 KB · Views: 11

IMG_3224.JPG204.3 KB · Views: 11