- Joined

- Sep 2, 2013

- Messages

- 5,418

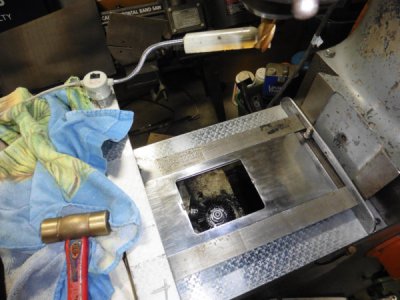

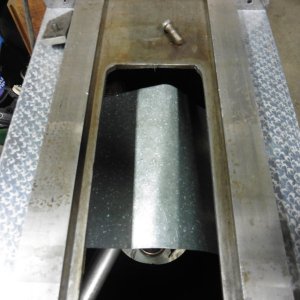

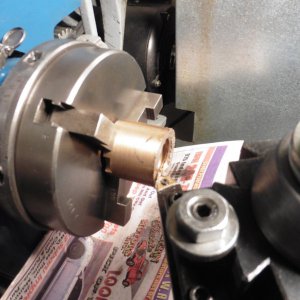

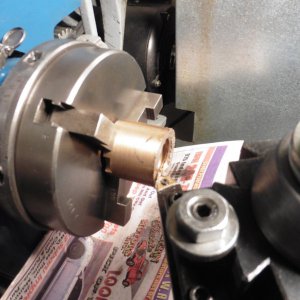

I went ahead and cut both the X & Y nuts and faced them off on the lathe. Used a Dremel to clean up the thread to match the factory end, which you can see was done by hand originally. Mocked up the Y axis (which was the worst) in the screw casting and it appears to have taken out all of the backlash. Will adjust them to spec when it all goes back together. Pulled the metal seals off all the feed screw end bearings including those for the knee crank and cleaned out the old dried grease and repacked them and replaced the metal seals. They turn nice and smooth now. Just got the ferules and nylon tubing in to replace all the oil lines. Will have about $50 total in the rehab. May get it all together before we head down to PR for the winter. If not it will have to wait until spring. Going down to Denver over the weekend to see our new grand daughter. Being my first, I'm pretty excited. Mike

Looking forward to getting home in April and finishing up. Mike

Looking forward to getting home in April and finishing up. Mike