I suggest we do some experimenting. Next time you tighten your vise on your mill table, mount a mag base on the side of the quill and put a .0001" indicator on the side of the T slot next to the T-nut and tighten it. See how much it moves. I am telling you this happens and with my 50+ years of experience I say it happens. You can take it or leave it.

The short answer is yes. I did a test and got a repeatable result. The table did deform in the area near the tee nut when the vise was clamped down. However, it was very slight, only .0001" (1/10,000") and the deformation went away when the nut was loosened up again. The vise in relation to the spindle did not move in the Z axis at all. So in a broader picture, the error is negligible and doesn't appear to be permanent, at least in my case.

How I did the test:

My mill is a RB-1 (Aka, First), basically a Bridgeport hybrid in a bed mill configuration, instead of a knee, It was manufactured in 1987 by Long Chang Machinery, Taiwan, It is very well made machine with Meehanite castings and chromed ways. It is in excellent condition.

After removing the vise I stoned and cleaned the table, I checked the table for any existing warpage. I used a 24" Starrett straight edge, I know its not a "scraped-in camelback" but I checked both edges on my granite surface plate, it was very flat not rocking or pivoting at any point, I could not get a .0005" shim under it at all. I got the same result on the mill's table, no discernible humps or high spots, the shim could not get under it at any point except in the flaking divots. When I deliberately put the shim under the rule it would distinctly pivot on spot. I moved the rule a few inches at a time, end to end and across. So I can safely say the table is flat to less than a half a thou in any 24"

Next, I checked the way travel by setting a tenths reading indicator on a magnetic base set on the bed and swept the movable length of the table, there was a slight rise at the far limits of travel about .0013" with the table moved all the way to the right and about .001" when moved all the way to the left. This is expected as the weight of the table hanging off one end causes the opposite end to rise slightly, this error only appears in the last few inches of travel. For most of the travel, the table showed no average change. Note, the leftwards travel is limited due to the X-axis power drive unit, that's why its error was slightly less.

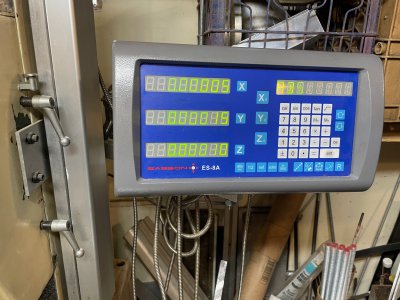

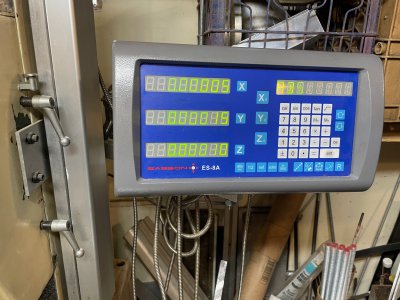

Next I mounted the vice back on, the center of the table first stoning and cleaning the bottom and then tramming it in. Both a vertical and horizontal sweep of the fixed jaw showed almost no movement with a Starrett last word test indicator .0005" res. Then I loosened stud nuts and set the indicator on the top center of the find jaw and retightened the nuts nuts, no visible movement on the indicator. Then I thought the quill's DRO has a 1μ .00005 (5/100,000") resolution, So I made a probe out of an inverted end mill and a ballbearing set in the center recess, I chucked it in the spindle and rested it on the top of the vise inline with the bolts. I put a bungee cord on the quill lever to put constant pressure I tightened the bolts and I got about .0001" rise. However on closer inspection I realized the ball bearing had made a small dent in the top of the vise and when I tightened the vise there was a slight movement on the Y axis causing the ball to ride up on the side of the dent and give the false reading. I then stoned the top of the vise and placed a square of carbide for the ball to rest on. Subsequent tests could not show any movement in the Z axis.

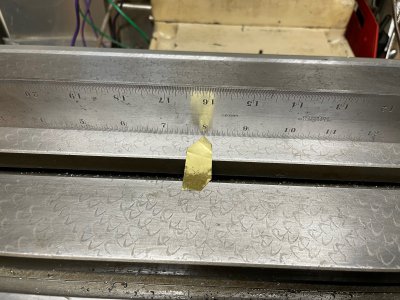

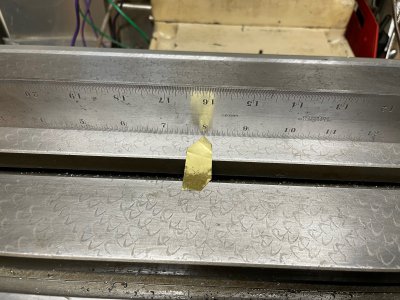

Next I checked the table around the area of the vice hold down nuts, with the probe, I got a .00005" rise but the diameter of the quill prevented me from getting in close and was in the way of the wrench. So I switched to tenths reading indicators, placing one as close to the nut as possible and one a few inches away as a control. Tightening the nuts showed a .0001" rise on the close indicator and no change on the far indicator. I repeated the test several times with and with out the probe on the vice and the nuts on both sides of the vice. All results were consistent, a one ten-thousandth bulge/distortion in the table surface at the immediate area around the nut, but no change in the vice itself.

Given these results, I did not proceed to make larger tee nuts to see if the they would "help" as the distortion was so insignificant, went away when the bolt pressure was relived and didn't affect the vise in any way. I don't think it's an issue for me. Of course these are my results, on one machine. IMHO The theory is still viable as a different, weaker table could possibly distort more and even retain some of that distortion. Anyone concerned should conduct their own test.