Good question.

I've been thinking about this for the last 2 hours. I like being challenged - it helps me to discover what assumptions I work with.

You have in interesting point there, and I'll try to address it also.

well said.

Let me go into some detail here: All really top-of-the-line tool posts use multiple techniques to prevent movement of the tool post. Unfortunately Aloris and Aloris-style tool posts don't. Look they

are good - I have one.

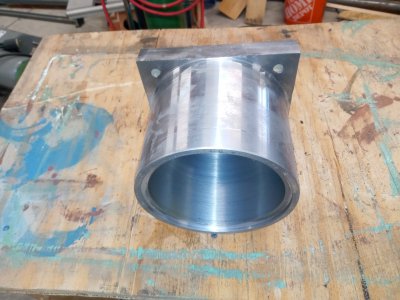

View attachment 445892

The force on the tool post can result in rotation, and also translation - movement across the face of the compound rest. In a typical Aloris style QCTP the only way to resist rotation is by friction from the tension of the bolt and the surface area in grey. The other movement can in part be controlled by the fit of the t nut by having friction on the red dotted line as well as the geometry of the bolt itself. By only having .020 between the T nut and the bottom of the tool post, there is a strong structure created where bending of the bolt is far more difficult. any strong force will then try to slide the T nut into the red dotted line. There is an unavoidable component of force going down the length of the T slot, but the far greater forces act on the grey area and the red dotted line.

What happens if the T nut is not tight fitting? You lose the firm seat for the end of the bolt, or seen another way, gives another surface that can slip - that is the underside of the compound-to top of the T nut connection. For less than an hour's work, you can eliminate this potential slipping surface.