- Joined

- Jul 21, 2015

- Messages

- 566

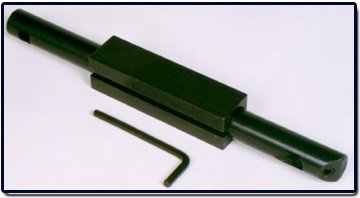

I have one of the two piece boring bar holders it handles 3/8 1/2 and 3/4 It is as solid as can be made.

I have one of the two piece boring bar holders it handles 3/8 1/2 and 3/4 It is as solid as can be made.

I didn't think you would take that deep of cut for your project. light cuts and a good sharp HSS bit and you should be fine. My bar probably a little more ridged than mild steel. Just posted to show 1/2 can work. Good luck. looking forward to seeing how you make out.

I never said the 4 way was the best.

I merely said that by it's very nature it is more rigid.

Boring bars for 4 way posts have a square sleeve for clamping, or have flats ground onto them.

As for deflection, if you are deflecting a flat or un-sleeved 3/4" (or even a 1/2") bar in any meaningful way, they you are way past proper torque.

(the set on the right is a Micro 100 set)

I am not sure what your point is. We all know that Aloris and other style QCTP's do the job for boring, and we all know that shimming is a drag (I even pointed that out). None of this changes the points I made above. As for a carbide bar, the OP was pretty clear that he did not want to spend the money on a piece of tool steel for just this job, I think it is safe to say that a carbide bar is also out of the question.

As for Dr. Heinrich, all I can say is be wary of a person who wears a lab coat and writes sales brochures. Those of us that have math degrees know that all we have to do is write a little bit of symbolic math and every one goes "OK, I take your word for it because you are obviously smarter than me." Any time I want my boss to leave me alone, I just start babbling about PDE's or the pros and cons of different ways of arriving at R^2 and she goes away. Seriously, I can just picture a conversation between a shop foreman and a machinist using Dr. Heinrich's math:

Boss: "Uhhhh, Bob, what are you doing?"

Bob: "Setting up the machine for boring."

Boss: "You need a calculator for that?"

Bob: "I have to calculate the modulus of deflection so I know how far above the centerline to set the tool."

Boss: <blank stare>

Bob: "See, the tool will flex down when I start the cut. Not only that, the tool will twist, so I also have to calculate the optimal depth of cut so the tool comes in line when it is under load."

Boss: "Ummm..."

Bob: "I am having a bit of trouble with this though. The optimal depth of cut does not work out with the chip load of my tool when I try to figure feed and speed."

<pregnant silence>

Bob: "I was about to call Dr. Heinrich at Micro 100 and see if he can help me get this straightened out."

Boss: "You're fired."

I suppose that a CNC machine dedicated to high production output of a single part would be set up like this. But this is a hobby forum, and we tend to use the "cut and adjust" method.

We can spend all day discussing clamping length, smoothness of clamping surface, etc. So we clamp our 3/4" boring bar to a 3" long holder full of confidence that we have a rigid set up. Then we drop the tool holder into a tool post that only has about a 2" diameter contact ring with the cross slide. A chain is only a strong as the weakest link.

A 4 way tool post is substantially larger than a QCTP, and has substantially more contact area with the cross slide. typically, you can also put a much larger tool into a 4 way than into a QCTP. Now, I agree that putting a round tool in a square slot will give poor results some of the time, but this is not the fault of the tool post, it is the fault of the user for not using the right tool.

Personally, I despise the 4way, and use an Aloris style QCTP. I am just not a blind to the fact that I gave up some rigidity for convenience. I have no experience with a real Aloris. Maybe it really is as rigid as a 4 way. I will probably never know, I can buy a used lathe for the price of an Aloris set.

Sorry for the delayed response - we're dealing with the death of a close family friend.

My point is that a boring bar held at two points of contact is not the most stable arrangement, regardless of the rigidity of the tool post. If you sleeve the bar or otherwise support it then that improves things but as we all agree, it has to be shimmed into proper alignment.I never said a 4 way post won't work; all I said was that he should test the set up before boring into something that already has some work in it.

The article I linked to is one of the few, if not the only article I've found, that discusses the comparative suitability of the available holder configurations. I found this information interesting and useful so I won't be impugning the guy. I've used all of these holders over the last 25 years or so and have settled on a circumferential holder in a QCTP because it performs the best and damages the bar the least. I've never had the post itself move so while it may not have the footprint or solidity of a 4way post, I don't care. What I do care about is that a solid holder is more important than the bar itself and I know, at least for myself, what that holder is.

In the end, none of this matters. Prasad was able to do the job with the tools at hand and it turned out okay. There are so many variables in boring that testing a set up before boring a piece with a lot of work in it is a worthwhile approach, which is what I intended to convey in the first place.

Sorry for the delayed response - we're dealing with the death of a close family friend.

My point is that a boring bar held at two points of contact is not the most stable arrangement, regardless of the rigidity of the tool post. If you sleeve the bar or otherwise support it then that improves things but as we all agree, it has to be shimmed into proper alignment.I never said a 4 way post won't work; all I said was that he should test the set up before boring into something that already has some work in it.

The article I linked to is one of the few, if not the only article I've found, that discusses the comparative suitability of the available holder configurations. I found this information interesting and useful so I won't be impugning the guy. I've used all of these holders over the last 25 years or so and have settled on a circumferential holder in a QCTP because it performs the best and damages the bar the least. I've never had the post itself move so while it may not have the footprint or solidity of a 4way post, I don't care. What I do care about is that a solid holder is more important than the bar itself and I know, at least for myself, what that holder is.

In the end, none of this matters. Prasad was able to do the job with the tools at hand and it turned out okay. There are so many variables in boring that testing a set up before boring a piece with a lot of work in it is a worthwhile approach, which is what I intended to convey in the first place.