-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

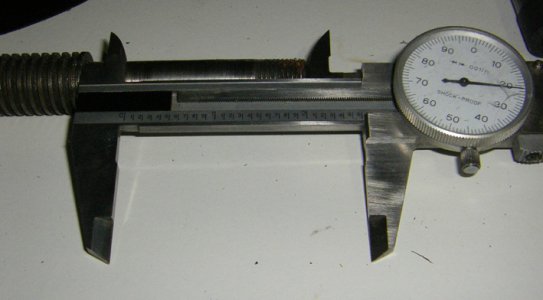

Atlas lead screw dimensions

- Thread starter iron man

- Start date

I just had Roton quote me aproximately 31 to ship my order which comprised of 1 3/4"-6 LH ACME thread @ 48", 2 1/2"-10 LH @ 12", and 1 1/2"-10 RH @ 12". Total with shipping just over $100. McMaster wanted $77 for just the 3/4"-6 part at 72". Their options were limited to pieces at 12", 36", and 72". At least according to my quick tour of their website. It's entirely possible I could get more exact dimensions if I phoned them as I did with Roton.

Terry

Terry

- Joined

- Feb 7, 2013

- Messages

- 792

Roton has a minium order I think its $60 I think my shipping for one piece 6' of 3/4 x 8tpi was $22 not too bad I guess. I dont know the grade of steel the roton one is for sure.. McMaster's has three grades the roton one will work just fine it machined a little rough with high speed steel but machined really nice with carbide.

Well I have a Frankenstein. Atlas 12" I think made around late 30s to early 40s and I'm guessing it was a special order because it has a 8 foot bed. I'm also guessing that it was used to make long tapered shafts like pool cues or something similar because it also has a tapering jig on the back also. I've been trying to restore it but it's a real pain trying to find parts for such a monster not to mention the setting for twist and levelRay,

The longest Atlas lathe has a 54" bed. Bed length is defined as the total length of the ways. Nominal, or rated, distance between centers on the Atlas 10" and Atlas or Craftsman 12" is 18" less than the bed length. So a 42" bed machine would be a 10x24. Up until about 1948, Atlas sold 10" and Sears sold 12" with bed lengths of 36", 42:, 48" and 54". The 36" and 48" beds were dropped around 1948. The 42" bed was dropped in the late 1970's (I haven't gotten around to pinning down the exact year).

Robert D.

They are one. Bed 8foot. Lead screw 3/4 acme. And yes the screw moves alot when using it and yes the bed is very hard to level and set up. I'm eventually gonna have to make a new drive screw or order one. The bed is OK got a few minor dings,rust on one in of flats and wear at the head stock from lots of use but I think it's manageable. I'd love to have a smaller bed for my atlas but where I'm located there's nothing. But one of these days I might find a 4ft or close to it. I'd hate to cut that 8foot down but I guess it's possibleInteresting. Are the bed and/or lead-screw one piece or two and if the latter does it appear that the bed and/or lead-screw were made from two each standard parts or one or two custom parts?

- Joined

- Dec 25, 2011

- Messages

- 10,552

Well, if you have no need for the 8' bed, you could probably cut it down to 54" LOA bed and turn it into a stock 54" LOA bed 36" between centers machine. You will have to drill and tap the headstock leg mounting holes. If you cut off and shorten the lead screw by discarding the headstock end, you should have a mostly unused lead screw. Depends upon how much the original owner used it for working long pieces. I don't think that you ever wrote specifically whether the machine was a 10" or a 12". But that really doesn't matter.

Yes it's the 12 atlas and I was thinking about cutting it down but everyone I talk to said it would be a sin to cut it down. But the more I think about it. It would definitely be cheaper for me to cut it down and use the best parts of the lathe to make one good lathe. Thanks for input. I'll try to keep everyone up to date on what I'm doing to my FrankensteinWell, if you have no need for the 8' bed, you could probably cut it down to 54" LOA bed and turn it into a stock 54" LOA bed 36" between centers machine. You will have to drill and tap the headstock leg mounting holes. If you cut off and shorten the lead screw by discarding the headstock end, you should have a mostly unused lead screw. Depends upon how much the original owner used it for working long pieces. I don't think that you ever wrote specifically whether the machine was a 10" or a 12". But that really doesn't matter.

- Joined

- Dec 25, 2011

- Messages

- 10,552

OK. I also have a 12" Atlas purchased in early 1981, Model 3996. To date, it is the highest serial number reported. However, it was made in late 1980. So it isn't quite the last one made.. What is your model number and serial number. And which type of cabinet is it in?.