-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas 7B Disassembly and Teardown! Pic Heavy!

- Thread starter Weldo

- Start date

- Joined

- Aug 3, 2017

- Messages

- 2,437

They have a generic "weldable 954 bearing bronze", which I think is the same idea. Oilite(the brand) doesn't seem to list rectangular/square bar stock as a thing, just round stock.

Hopefully someone more knowledgable can give a better opinion here though.

Hopefully someone more knowledgable can give a better opinion here though.

- Joined

- Dec 23, 2019

- Messages

- 1,138

EDIT: just seen the PDF: the block is oilite! I was looking at the washer, but that's brass. So your block is a replacement, presumably for a worn or broken block. Oilite plate is available, but it's going to cost. I reckon a bearing bronze block would probably do the job, though you might have to modify the oiling arrangements.

Last edited:

- Joined

- Sep 7, 2019

- Messages

- 674

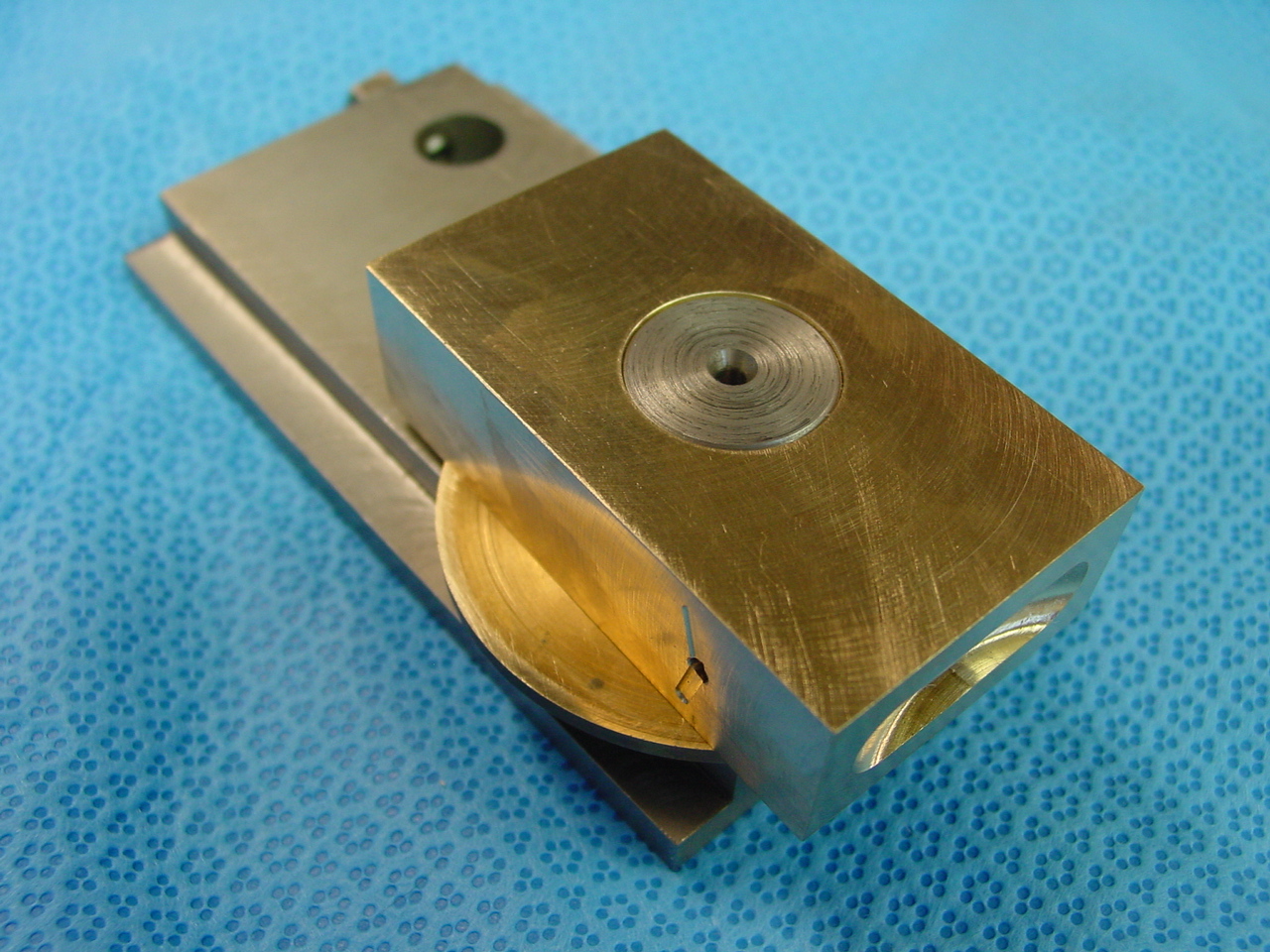

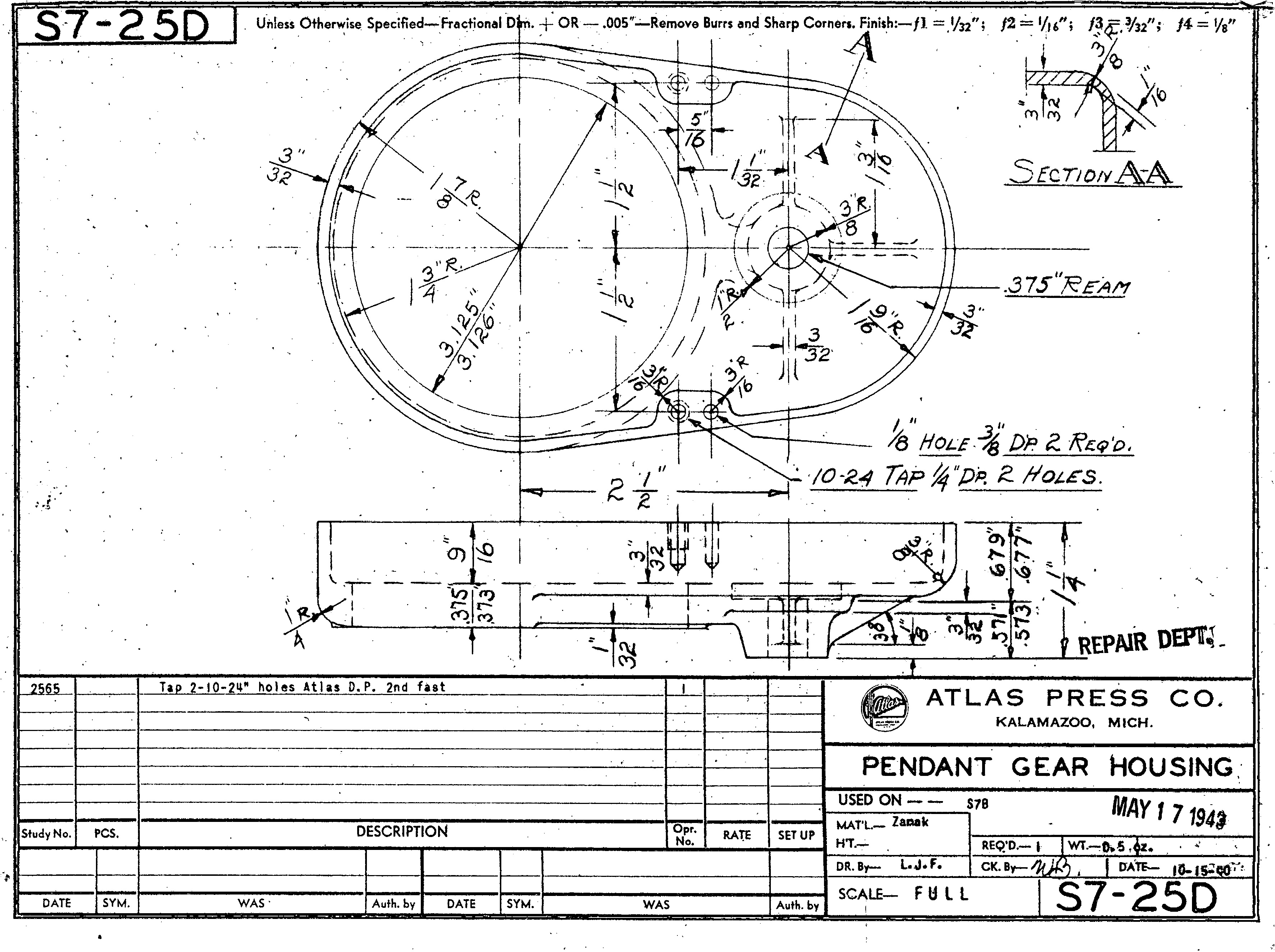

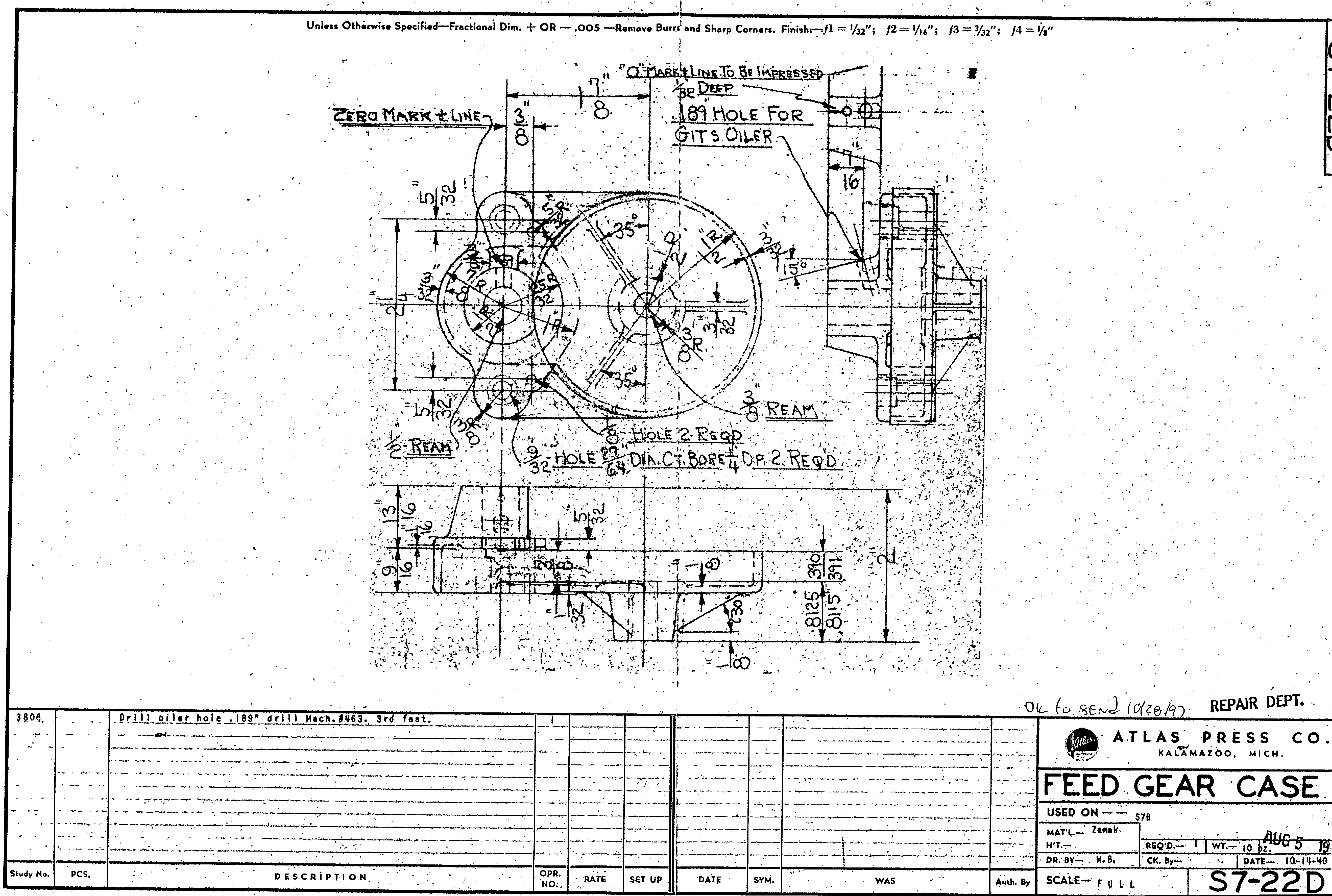

Got some more drawings from Clausing! I just sent another request and they answered in like 20 minutes!

These two drawings are some of the crappy ZAMAK parts. I was curious if I could make these housings from scratch in fabricated steel as opposed to casting or machining.

I wanted S7-22, S7-23, S7-24, and S7-25, but it turns out they don't have drawings for 23 and 24.

These two drawings are some of the crappy ZAMAK parts. I was curious if I could make these housings from scratch in fabricated steel as opposed to casting or machining.

I wanted S7-22, S7-23, S7-24, and S7-25, but it turns out they don't have drawings for 23 and 24.

- Joined

- Aug 3, 2017

- Messages

- 2,437

The shapes to those components are pretty simple, they were cast for cost effectiveness I think.

I pulled my feed selector apart to see how it works, it seems like it would be pretty trivial to remake! Same with the other two castings.

I pulled my feed selector apart to see how it works, it seems like it would be pretty trivial to remake! Same with the other two castings.

- Joined

- May 3, 2017

- Messages

- 2,026

Congratulations on your find. Looking forward to following your progress. I just finished a similar project on a pristine South Bend. Not nearly as picture-heavy as yours, but here's a link.

Regards,

Terry

www.hobby-machinist.com

www.hobby-machinist.com

Regards,

Terry

Look what showed up in my shop!

A friend just got this gem and wants me to keep it in my shop - indefinitely - no, really. I've wanted one of these for a long time, but I doubt that I could have found one in this condition. It's a South Bend #7, and if you look through the dust, it appears to be in near mint condition. It...

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Sep 7, 2019

- Messages

- 674

I'm almost done washing parts. I've found another small issue.

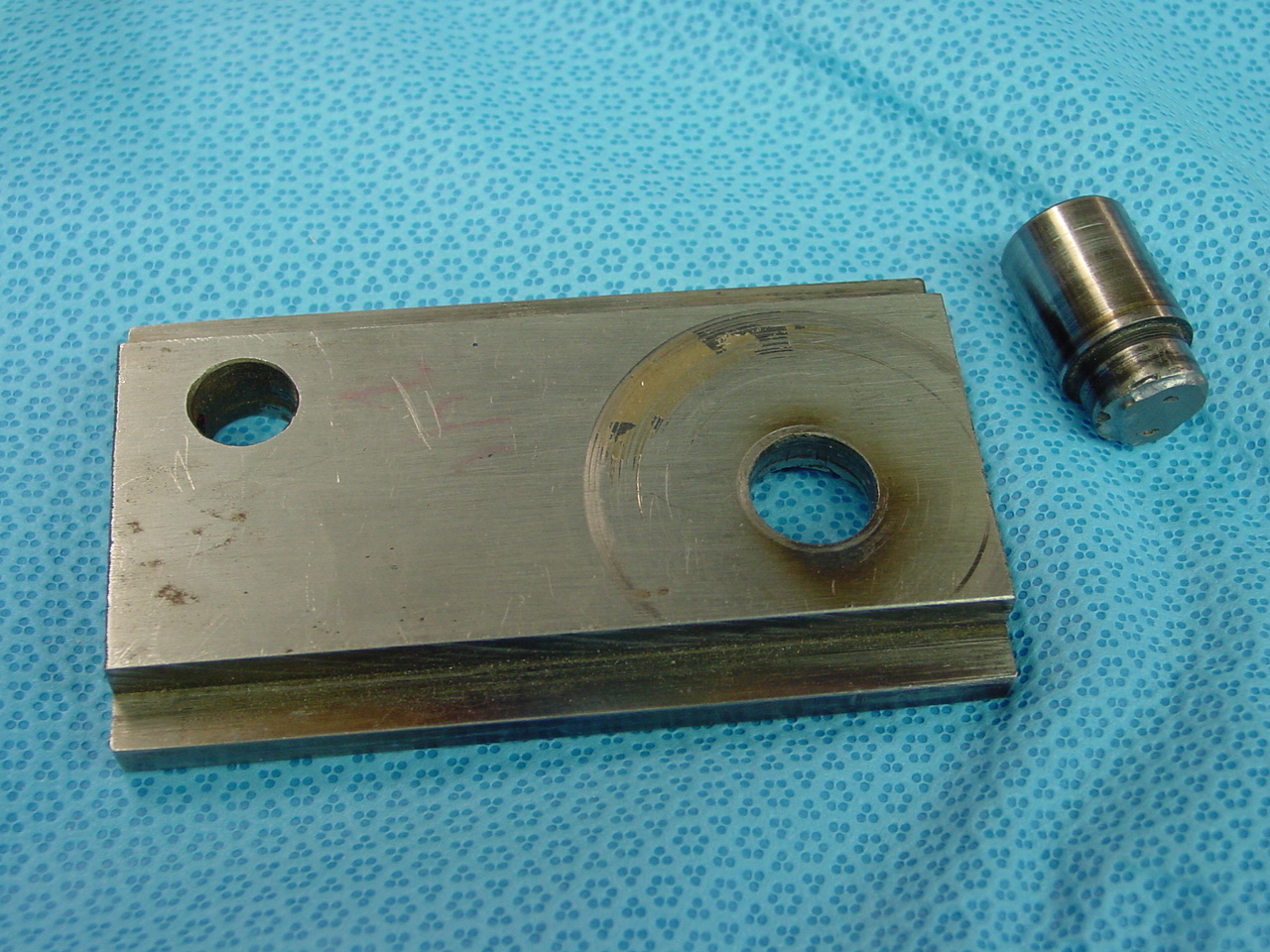

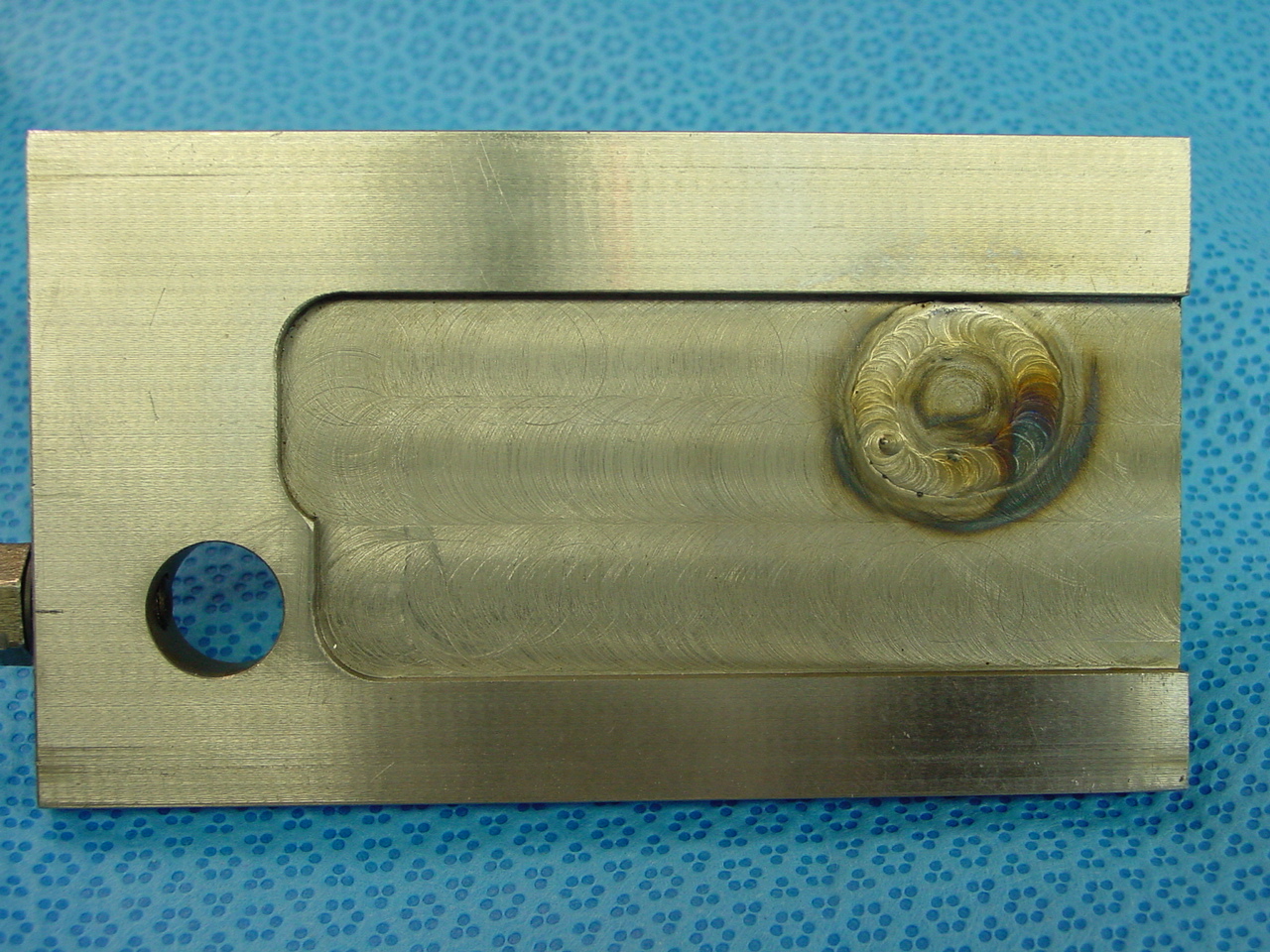

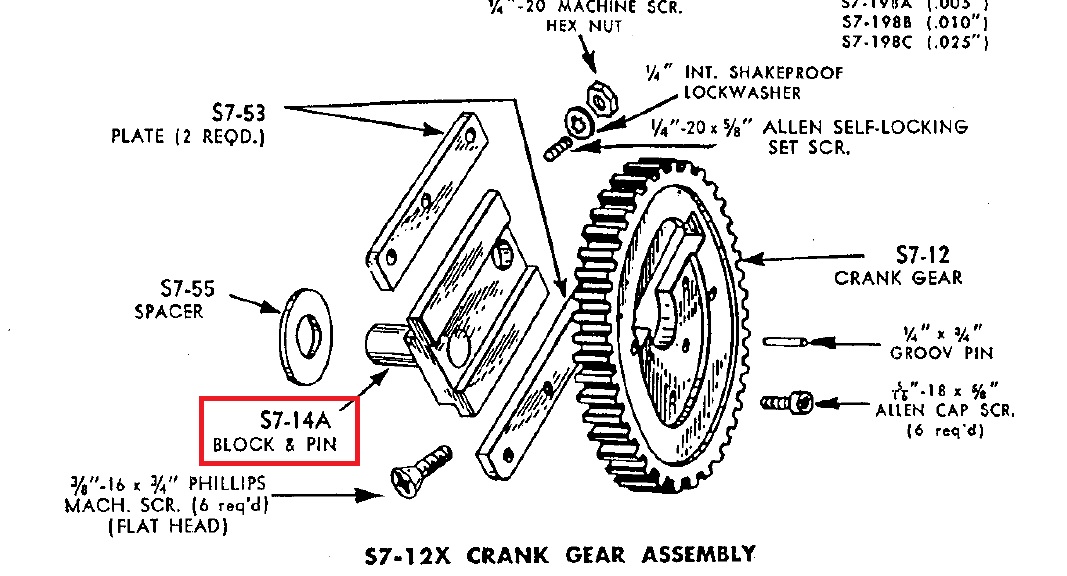

The plate in the picture is S7-14A in the diagram below.

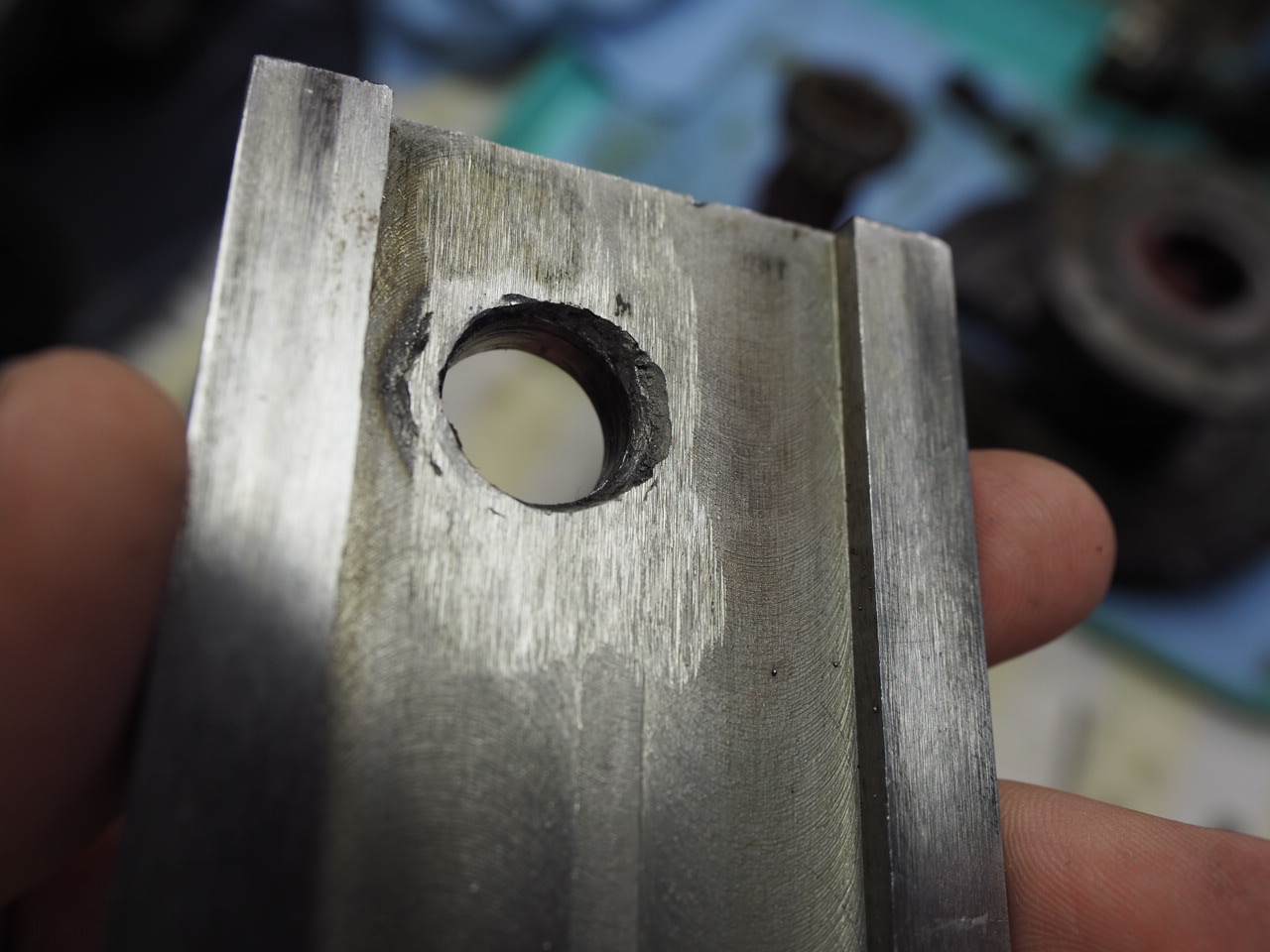

I'm guessing that the pin is supposed to be a tight press fit into the plate, however mine has been welded and ground flat. I didn't take a pic before I punched the pin out but you could see crack lines running around the circumference of the pin on the back side. Also the pin had a tiny bit of wiggle and I could see the cracks opening and closing ever so slightly as I wiggled the pin.

So I punched the pin out.

You can see the broken weld around the backside of the pin.

And the broken weld around the hole. Some of the weld is hanging on tight on the left side there. I'll try to countersink it out as much as I can.

I'm reluctant to weld on an already machined part but someone else already has apparently, so it shouldn't be too catastrophic. I'll bevel and chamfer the parts and lay a hot TIG weld in there. Might have to choose filler carefully since the pin is likely, and the plate is maybe, hard tool steel.

There is also a grinded portion on the other side of the plate. Not sure why this was done, but I don't think it will affect anything else.

This is the first very major issue I've found. Other than this there are a few small cracks in the zamak parts and some chowdery lookin stake marks on some of the bolts. I'll post more pics as I clean the parts up.

All in all not too bad for a 60-70 year old pseudo-industrial machine.

The plate in the picture is S7-14A in the diagram below.

I'm guessing that the pin is supposed to be a tight press fit into the plate, however mine has been welded and ground flat. I didn't take a pic before I punched the pin out but you could see crack lines running around the circumference of the pin on the back side. Also the pin had a tiny bit of wiggle and I could see the cracks opening and closing ever so slightly as I wiggled the pin.

So I punched the pin out.

You can see the broken weld around the backside of the pin.

And the broken weld around the hole. Some of the weld is hanging on tight on the left side there. I'll try to countersink it out as much as I can.

I'm reluctant to weld on an already machined part but someone else already has apparently, so it shouldn't be too catastrophic. I'll bevel and chamfer the parts and lay a hot TIG weld in there. Might have to choose filler carefully since the pin is likely, and the plate is maybe, hard tool steel.

There is also a grinded portion on the other side of the plate. Not sure why this was done, but I don't think it will affect anything else.

This is the first very major issue I've found. Other than this there are a few small cracks in the zamak parts and some chowdery lookin stake marks on some of the bolts. I'll post more pics as I clean the parts up.

All in all not too bad for a 60-70 year old pseudo-industrial machine.

- Joined

- Sep 7, 2019

- Messages

- 674

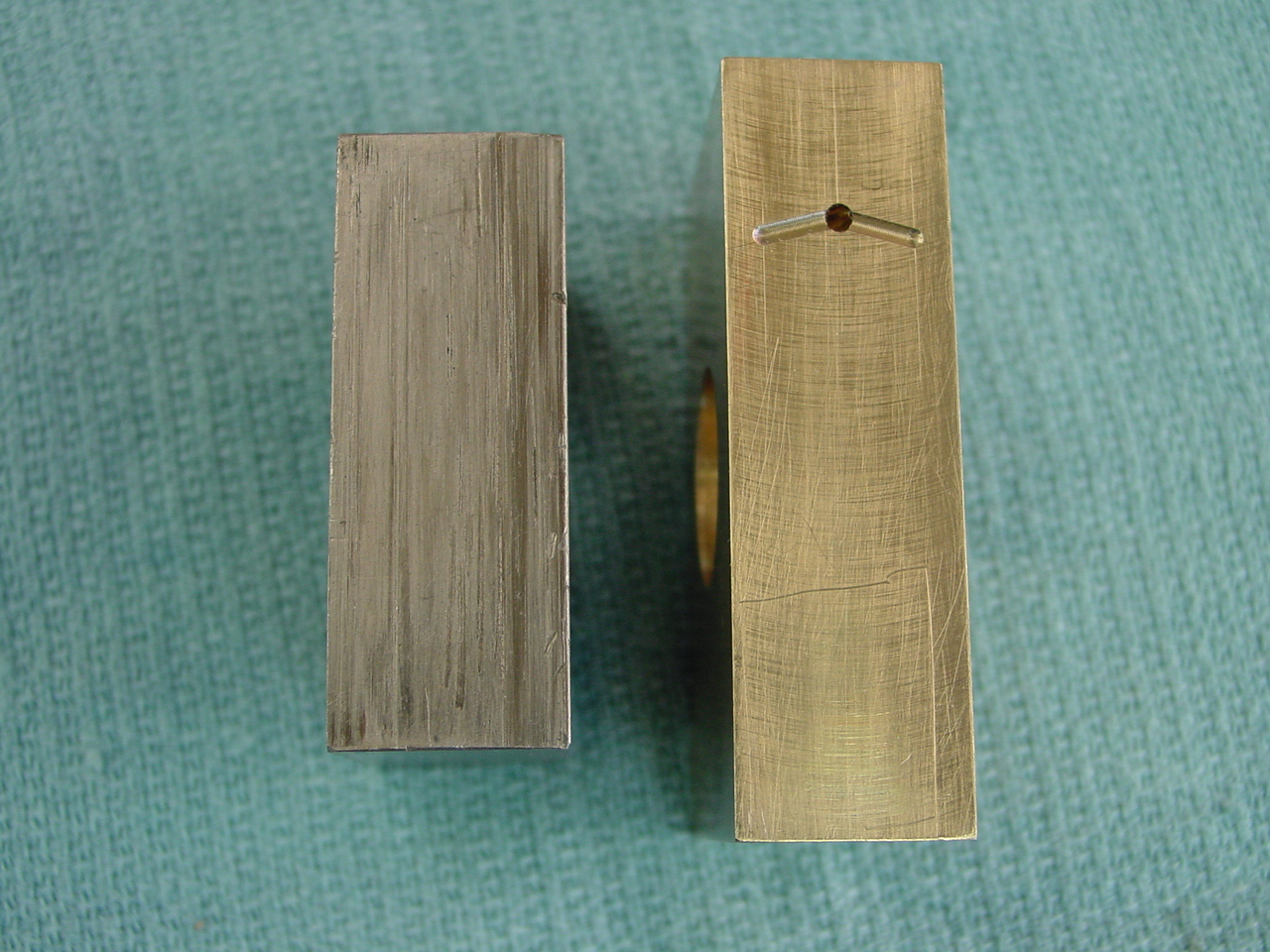

Just found this pic on ebay. Same used part I pictured in the previous post.

Maybe the weld on the pin is factory. Or maybe this one has been repaired in the same way mine has. What are the odds? Looks like this piece doesn't have the grinded portion mine has though.

I also found this pic on ebay:

This block doesn't really look like Oilite, does it? It doesn't have brass on it like mine does.

Maybe the weld on the pin is factory. Or maybe this one has been repaired in the same way mine has. What are the odds? Looks like this piece doesn't have the grinded portion mine has though.

I also found this pic on ebay:

This block doesn't really look like Oilite, does it? It doesn't have brass on it like mine does.

- Joined

- Jun 27, 2016

- Messages

- 384

I made a lot of the same parts that you found worn or broken. But it gave me an opportunity to improve them.

The sliding block,

The sliding block,

- Joined

- Jun 27, 2016

- Messages

- 384

My crank pin was broken too and was repaired before in the weld area, guess what, it was broken again, so I remade the whole assy. On the new one I press fitted the pin then TIG welded, hopefully it won't break like the original.