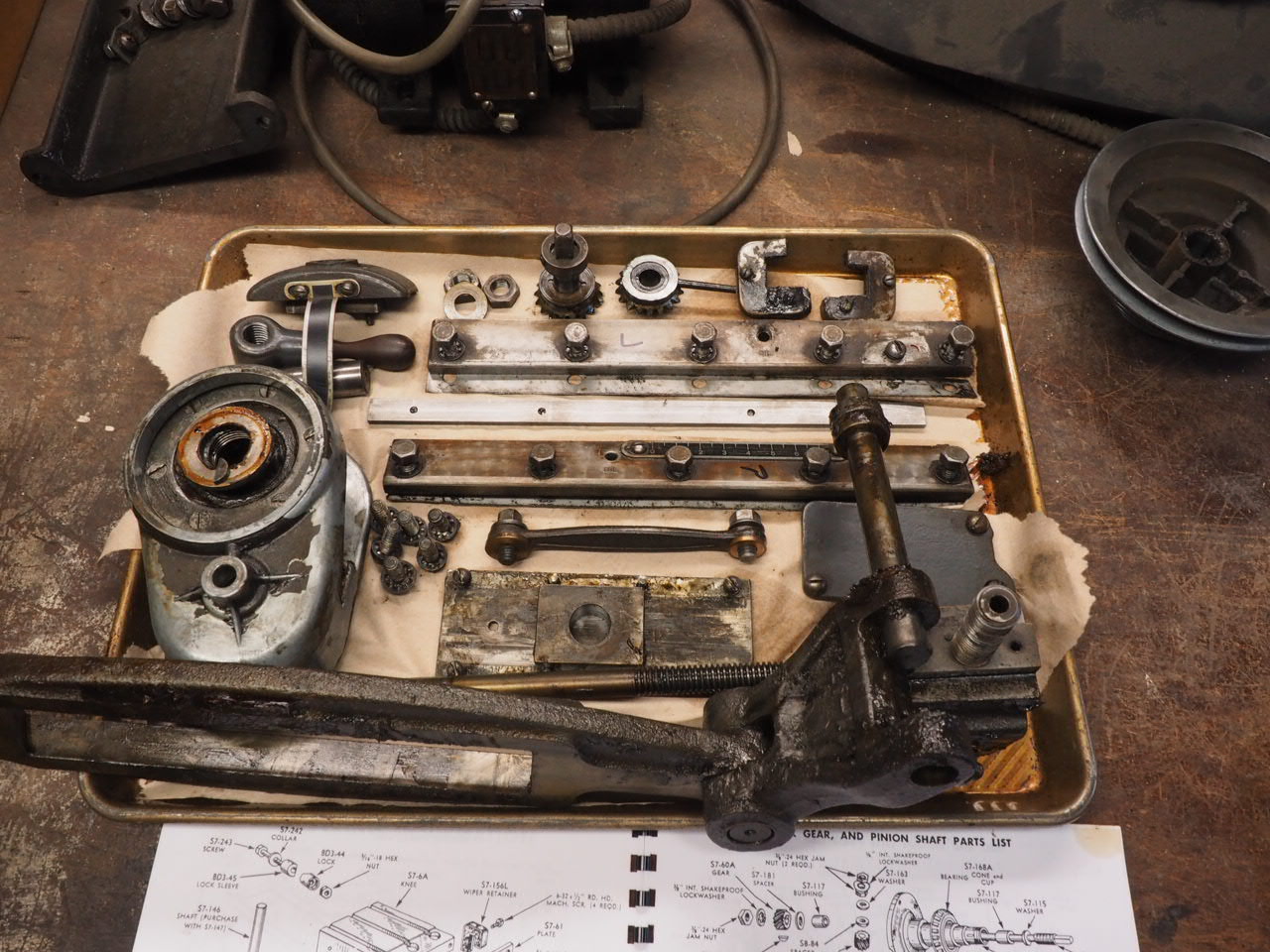

For that spacer, I'd measure the amount that the block itself is 'lower' than the plate (or the surrounding parts), and subtract a couple thou. You can see in your picture that the block is a few thou 'low' and that the shaft itself is 'high'. I think you want to make it just shy of even with the bottom of the plate.

I'm guessing your repair is just that, a shop-time repair. Fortunately, braising is going to be about as soft as the stock brass, I'm guessing it wore out and someone just filled it in and re-ground it flat. It appears to me that the block isn't particularly complicated of a part, so it seems like it would be easy enough to remake if you needed to.

Side note:

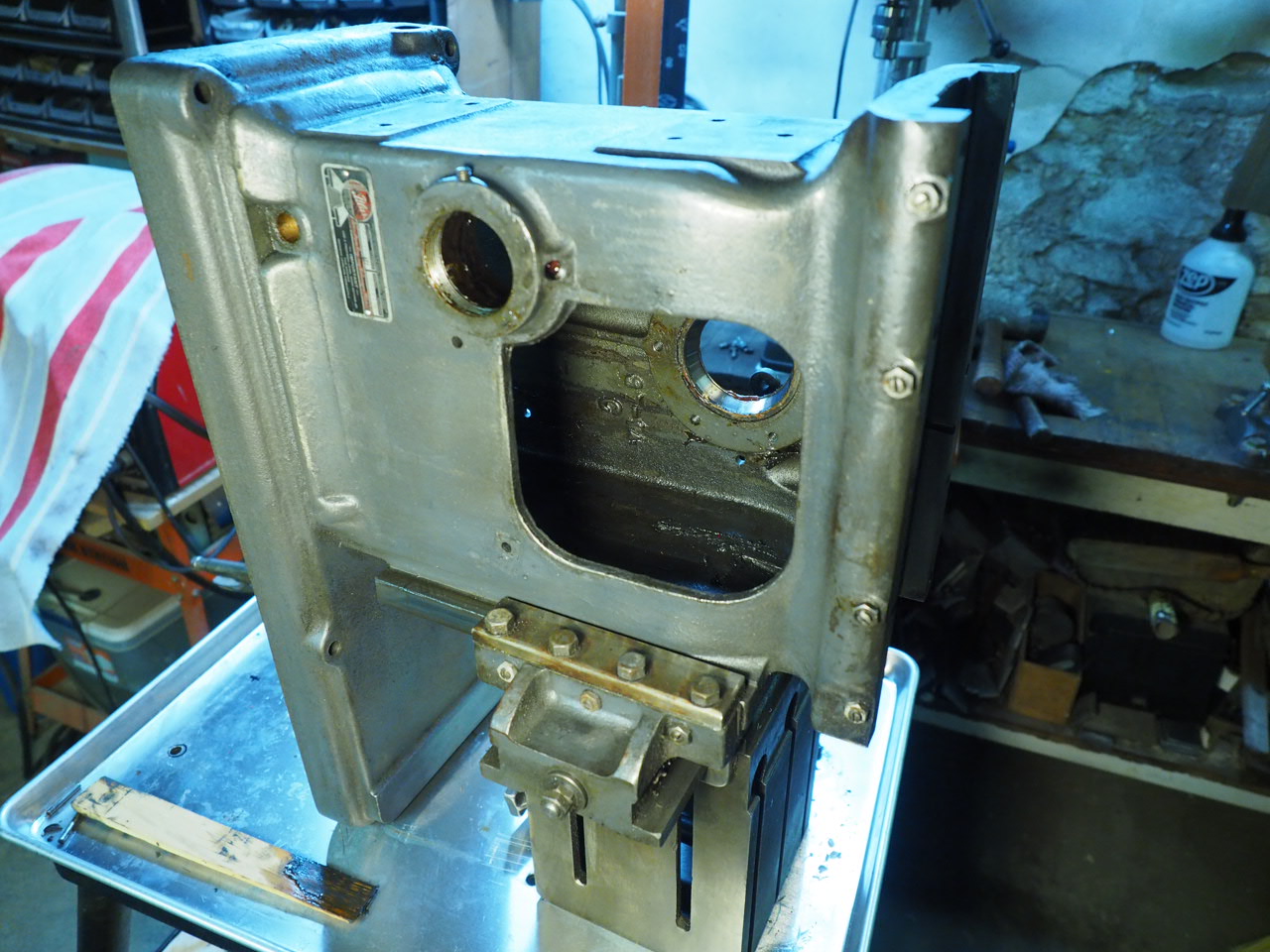

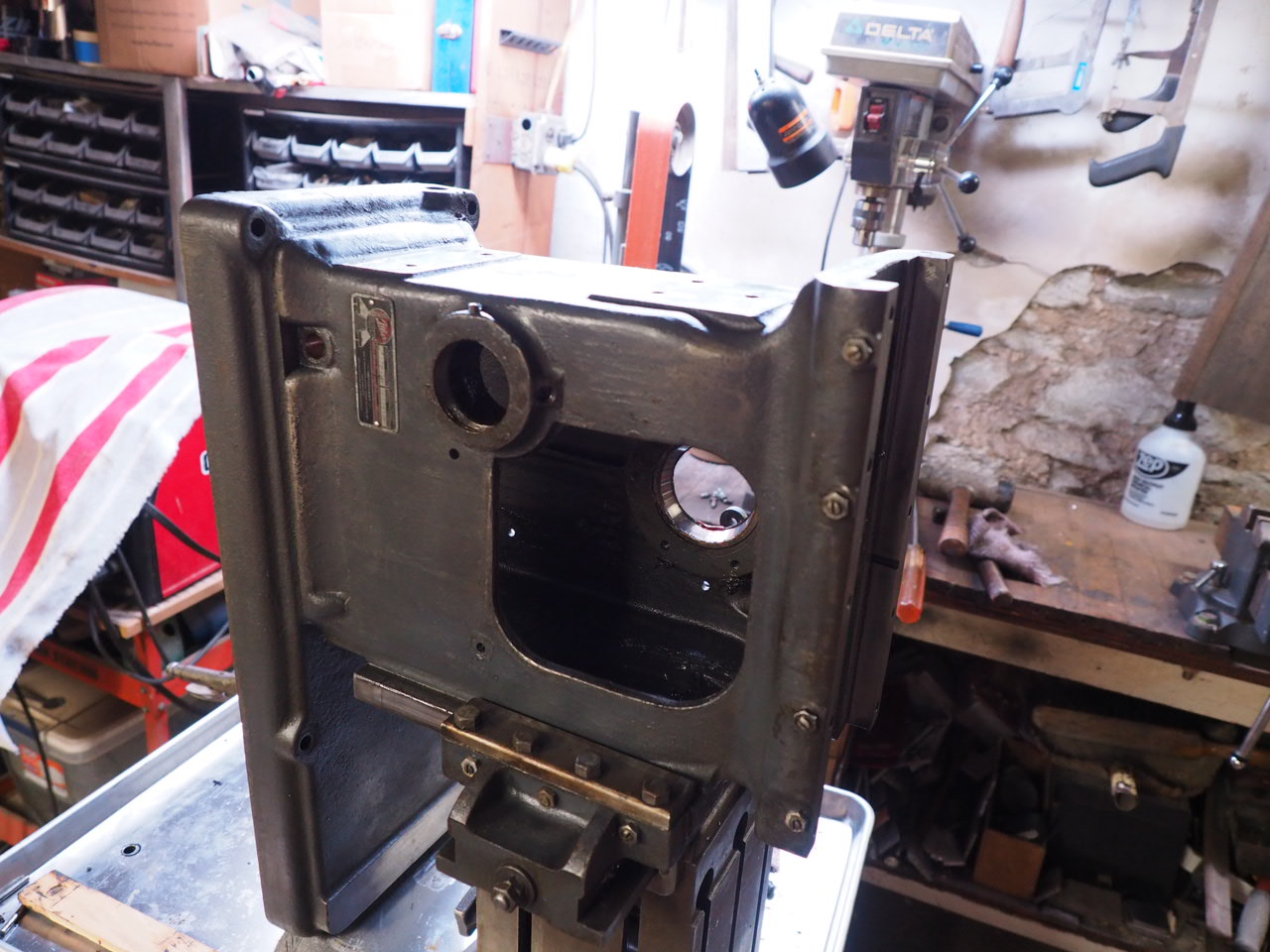

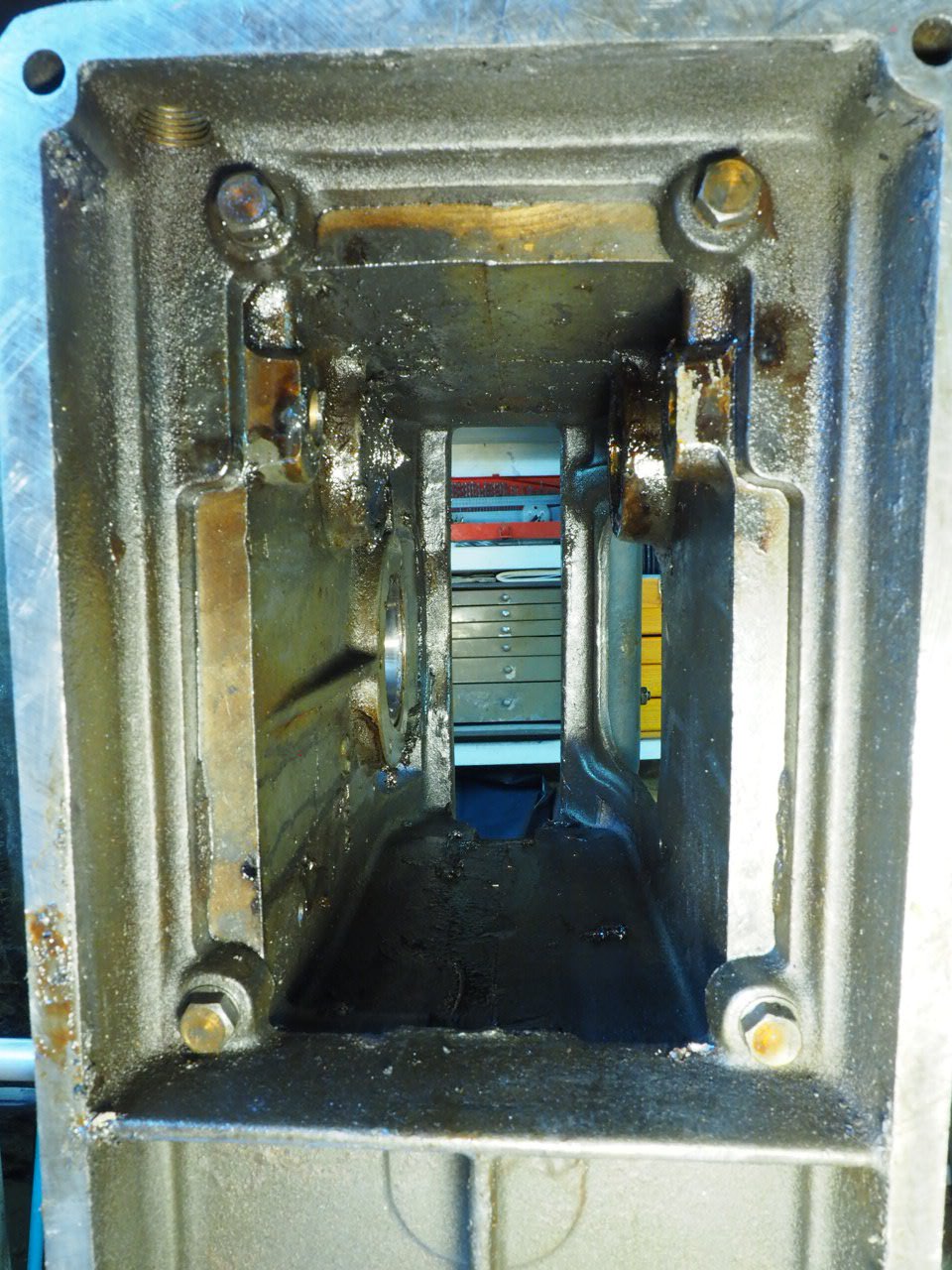

This thread has already been useful to me! I was shapering today, and my shaper got stuck. It turns out, the step pulley on the machine-side was slipping! I pulled it apart (which required pulling off the gears behind the stroke adjustment adjustment) on the way to pulling off the entire outer casting (so the 'ring' behind the gear, then the back half of that casting) and got to the little ring! It wasn't obvious that it was threaded on, but I saw your post before checking it out, so I knew to thread it off!

Turns out, someone had re-assembled my step-pulley without the key at one point. It seemed to be a 1/8"x1/2" woodruff key. Unfortunately, the closest I had was 5/32"x1/2" flat bottom! This required surface grinding it thinner, and taking some material off the top to get the height correct (thank you machinery handbook!).

However, after a little more than an hour (and a dirty me + dirty phone from checking out your pictures!), I was back to work! I ended up making some T-Nuts for my mill, which has an annoyingly slightly-under-9/16" T-slots, but not smaller enough (nor new enough, its a 1960s millrite!) to be metric. Most of my T nuts have been bench-grindered to size, so it'll be nice to have decent ones. AND I got to play with all kinds of cuts (including 7" on the shaper!).

Final side-note, I got the speeds/feeds diagram from the manual printed at VistaPrint. It was $20 or so, but it seemed like a great addition to the shop, so that I could mount it behind the machine.