I'm in the camp of those that consider the DD crap. I've tried them twice, once many years ago and again in 2017. I'm no slouch when it comes to figuring out how to use a tool/machine, but I could never get even close to satisfactory results. Even with the more recent model (up to 3/4" capacity with adjustable relief ange, IIRC), I did not like the relief angle, but most of all I though the grind finish was horrid (first photo). I tried the finer, 180 grit wheel, but even that was too gross. I'm comparing to factory finish on Precision Twist Drills.

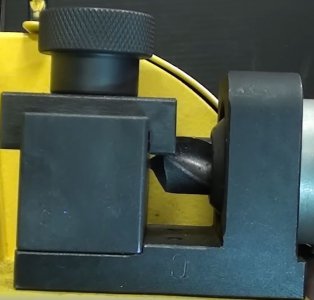

It was at the end of my DD trials in 2017 that I came across the Tormek wet grinding sharpening system and in looking at its drill bit jig, I discovered the clamping block that holds and aligns the drills was almost exactly like that on a professional drill bit sharpening machine that I had used in a friend's shop (second photo). Not a collet system like the Vevor, which looks to be excellent, but a positive clamping and alignment method, which when set up correctly is flipped over on the table for grinding opposing flutes. This was enough to push me past the huge price of the Tormek, knowing that it also sharpens a wide range of tools, many of which I use and need sharpened.

The stock/standard Tormek grinding wheel is around 220 grit and can be graded finer, closer to 1000 grit and produces a much finer finish, much closer to the factory finishes I wanted (third photo, showing a 4-facet grind) - on my first attempt. The Tormek is not fast, especially for roughing and heavier grinding. Initially, I set it up with a traditional Norton 3X bench grinder wheel, which worked very well (fourth photo). This is also my best photo of the overall setup, even though it isn't with a Tormek grinding wheel installed. I have since added a CBN 180 grit and diamond wheels at 320, 600, and 1200 grit which produce spectacular finishes. I have a 4000 grit Japanese wheel but have not used it on drills yet, but I have on knives and scissors.

I am very impressed with the Vevor, at least from watching the review videos. There are two aspects of the Tormek that are less than optimal, 1) visual alignment of the flutes relative (first step with the Vevor, on the left side) and 2) speed. Both of these are implemented much better with the Vevor, from what I can see on the review videos. I especially liked Tubelcain's view of the flute alignment setup, very positive (fifth photo). And quite clearly, the Vevor would be much faster. I am also very impressed with the Vevor ER collet chuck system and that it will go down to 3/32" diameter drills. The Tormek says it will go down to 1/8", but the clamping system does not function well with such small drills. I have worked around that by holding smaller drills in a pin chuck (sixth photo).