-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice for Dove tail Milling First Time

- Thread starter jlsmithseven

- Start date

- Joined

- Jan 16, 2017

- Messages

- 216

where did you get these numbers from?The constant for a 1/4" rod at 60 degrees is 1.1830" so if you can find that rod and use it, the distance between them should be 1.771 - 1.1830 = 0.588".

- Joined

- Jan 16, 2017

- Messages

- 216

The dovetail width is the overall dimension I need to meet.What exactly are you measuring at 1.771"?

- Joined

- Jan 26, 2015

- Messages

- 1,939

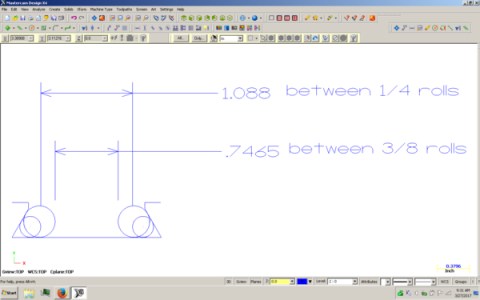

Dovetails are usually dimensioned with rolls. The overall should fall in if the dimension between the rolls is met. The reason the rolls are used is because it is almost impossible to measure into the corners of the dovetail accurately.

Last edited:

- Joined

- Nov 5, 2016

- Messages

- 1,420

What tolerance do you need to hold? Maybe someone else suggested this and I missed it, but if it were me, I'd machine a bar for the diameter you want and cut it up into two pieces of the desired length... Unless you lathe has a bad taper to it, the two pieces should end up close to the same diameter. If you have a taper, polish/file until the bar is true before cutting the pieces to length. As long as they are both the same diameter, you should be able to calculate the rest.

Just a thought,

Ted

Just a thought,

Ted

Last edited:

- Joined

- Dec 3, 2014

- Messages

- 778

In post #1 the drawing dimensions tolerances are screwy IMO. + - .005" for the dovetail width is going to leave you with pretty small chance for success. It has been my experience doing dovetails on both a mill and shaper that you need to hit +- .001 for the width dimension of dovetail unless you want your dovetail to be very sloopy. Once you have done a couple dovetails I think you will find you want to sneak up on your final dimension and try to take cuts of less than a thou at a time if you want a tight sliding fit. One thou difference can take you from just too tight to noticeably loose in my experience.

- Joined

- Jul 2, 2014

- Messages

- 7,594

+1 on the tolerance for the dovetails. That is a precision dimension, not to be taken lightly unless you have a good use for scrap metal tool holders...In post #1 the drawing dimensions tolerances are screwy IMO. + - .005" for the dovetail width is going to leave you with pretty small chance for success. It has been my experience doing dovetails on both a mill and shaper that you need to hit +- .001 for the width dimension of dovetail unless you want your dovetail to be very sloopy. Once you have done a couple dovetails I think you will find you want to sneak up on your final dimension and try to take cuts of less than a thou at a time if you want a tight sliding fit. One thou difference can take you from just too tight to noticeably loose in my experience.