- Joined

- Aug 8, 2024

- Messages

- 5

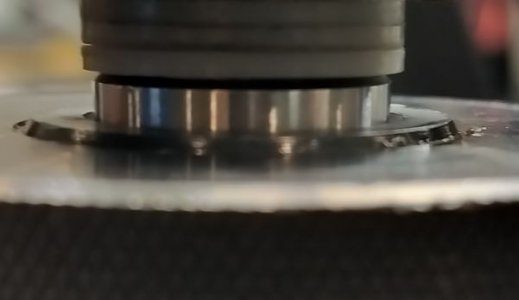

Hi All, I was wondering if there is an acceptable tolerance between the visibility of the arbor taper and socket when mounting a drill chuck. I'm using a 1/2" straight shank arbor to JT3 which is going to a new Shars JT3 keyless drill chuck. The visibility of the taper is about 1/8" or 3mm when fully seated. The taper itself when test fitting feels snug and concentric, no wiggle to suggest that fitment is off. (the first picture showing the silver shaft of the taper, the second picture where you can only see the chamfered edge of the taper)

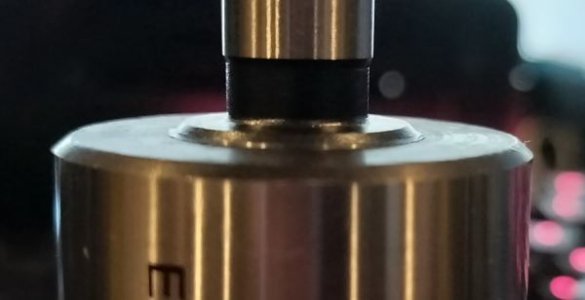

On another part for another project, I'm also using a 1/2" straight shank arbor to JT3 taper to an er32 collet holder. Yet when test fitting, the taper sits more flush where it comes together. And again on this one, feels snug, concentric no wiggle, and more so looks fully seated.

Is this kind of visibility acceptable for a drill chuck? or should I be looking to make sure it sits like how the other one fits? I don't mind the visibility of the taper as it is minimal, but would rather make the correction if it SHOULD be done as so.

Thanks on any insight you guys might be able to share.

On another part for another project, I'm also using a 1/2" straight shank arbor to JT3 taper to an er32 collet holder. Yet when test fitting, the taper sits more flush where it comes together. And again on this one, feels snug, concentric no wiggle, and more so looks fully seated.

Is this kind of visibility acceptable for a drill chuck? or should I be looking to make sure it sits like how the other one fits? I don't mind the visibility of the taper as it is minimal, but would rather make the correction if it SHOULD be done as so.

Thanks on any insight you guys might be able to share.