-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A "Good Enough" Mill Vise?

- Thread starter MaverickNH

- Start date

- Joined

- Nov 6, 2012

- Messages

- 159

I was skeptical about the specs for squareness of the jaw to the bottom parallel. As it turns out, a 3-in vice is my maximum capacity, as a 4-in will overhang too much and cut off my y-axis travel. So I'm thinking to just get a better 3-in vise.Is the one you have already not "good enough", or are you just wanting a bigger vise?

John

- Joined

- Jan 4, 2021

- Messages

- 3,279

Not too tall (although at times my 3" [w/o swivel] is a little tall, even though I have a 2" riser block on my column), too long:Maybe you've just saved me from making a "too big" mistake!

The 3" vise that came with my starter kit is 3.05"/4.21" in height (with & without the swivel base). I took off the swivel base.

A 4" vice is 3.5" in height w/o the base. I'm wondering what makes it too big for a LMS 3990? It's about twice the weight of a 3"...

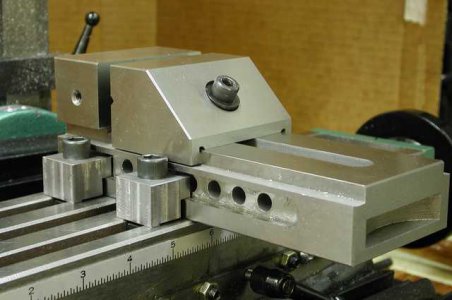

My 3" (with wider/taller outside jaws mounted) next to a Kurt DX4 (OK, a paper template at ~97% that I made from the drawing in the DX4 manual). I have my 3" mounted so that I can get the OD of a 3/8" end mill past the inside faces of the regular jaws at the full Y-Axis travel and thus machine the edge of the largest part that will fit between the jaws. If I need to clamp a part that is larger than the 3"W x 3-1/16"L jaw opening, I uses the 3-1/2"W x 8-1/8" opening provided by the outside jaws.

I've attached a PDF of the DX4 I made if you want to play with it yourself, just be sure to print at 100%; unless you have a large format printer you'll need to do some actual cutting & pasting.

Attachments

- Joined

- Jan 4, 2021

- Messages

- 3,279

I was busy playing with my flat DX4 so our posts crossed.I was skeptical about the specs for squareness of the jaw to the bottom parallel. As it turns out, a 3-in vice is my maximum capacity, as a 4-in will overhang too much and cut off my y-axis travel. So I'm thinking to just get a better 3-in vise.

Not as precise/rigid as a true milling vise, and a little taller than my 3", a 4"self-centering vise will give you more width and Y- capacity and still fit on the table. Here's mine:

- Joined

- Dec 18, 2019

- Messages

- 7,650

Another option, that is quite rigid, but not quite as easy, is a tool maker's vise. I have a 3" tool maker's vise and use it on my PM25 mill at times. I bought it from Little Machine Shop as a blem. At the time, it was about $100. I modified mine to use a stud and nut, instead of a screw, but they are perfectly useful with just a screw. https://littlemachineshop.com/products/product_view.php?ProductID=4871&category=

Still $99 for the blem - with the preferred slot tie downs.

A little more for the clamps. I machined my own clamps, but the one's for sale will work fine. For these small vises, you may find the 6" parallels are a bit unwieldy. I bought some 3" parallels from LMS (when they went on sale). For bigger stuff, just clamp to the table. Sometimes you need to use a sacrificial spacer, or you use 123 blocks as the spacer (with care).

I bought my toolmaker's vise and used it as a primary vise for about 5 months, while waiting for a Kurt DX4 to go on sale. The Kurt is easier to set up, but the toolmaker's vise has less jaw lift. I know, because I measured it.

Still $99 for the blem - with the preferred slot tie downs.

A little more for the clamps. I machined my own clamps, but the one's for sale will work fine. For these small vises, you may find the 6" parallels are a bit unwieldy. I bought some 3" parallels from LMS (when they went on sale). For bigger stuff, just clamp to the table. Sometimes you need to use a sacrificial spacer, or you use 123 blocks as the spacer (with care).

I bought my toolmaker's vise and used it as a primary vise for about 5 months, while waiting for a Kurt DX4 to go on sale. The Kurt is easier to set up, but the toolmaker's vise has less jaw lift. I know, because I measured it.

This is exactly what I did when I had a Smithy (my first machine). At the time it was the only good vise I could get that fit. And it worked fine. In fact, I still have it and use it for the occasional vise-in-a-vise setup.Another option, that is quite rigid, but not quite as easy, is a tool maker's vise. I have a 3" tool maker's vise and use it on my PM25 mill at times. I bought it from Little Machine Shop as a blem. At the time, it was about $100. I modified mine to use a stud and nut, instead of a screw, but they are perfectly useful with just a screw. https://littlemachineshop.com/products/product_view.php?ProductID=4871&category=

Still $99 for the blem - with the preferred slot tie downs.

A little more for the clamps. I machined my own clamps, but the one's for sale will work fine. For these small vises, you may find the 6" parallels are a bit unwieldy. I bought some 3" parallels from LMS (when they went on sale). For bigger stuff, just clamp to the table. Sometimes you need to use a sacrificial spacer, or you use 123 blocks as the spacer (with care).

I bought my toolmaker's vise and used it as a primary vise for about 5 months, while waiting for a Kurt DX4 to go on sale. The Kurt is easier to set up, but the toolmaker's vise has less jaw lift. I know, because I measured it.

GST

- Joined

- Dec 10, 2023

- Messages

- 133

I refer to this type of vise as "screwless" as that is how it was listed when I bought it and is the most common reference I've seen. I've been using the same 3" screwless vise for nearly 25 yrs, first on a minimill, then on an milldrill and now on a 2x26 knee mill. I do this partly because the machines I've had don't really have the capacity for larger vises but more so because I like how they work and their precision. One of the strongest advantages is that the moveable jaw do not spring, closing tighter and more parallel/perpendicular and I don't have to hammer on the parts as much to seat them snugly on parallels. In addition, it's footprint is much smaller and overall height is lower.Another option, that is quite rigid, but not quite as easy, is a tool maker's vise. I have a 3" tool maker's vise and use it on my PM25 mill at times. I bought it from Little Machine Shop as a blem. At the time, it was about $100. I modified mine to use a stud and nut, instead of a screw, but they are perfectly useful with just a screw. https://littlemachineshop.com/products/product_view.php?ProductID=4871&category=

Still $99 for the blem - with the preferred slot tie downs.

A little more for the clamps. I machined my own clamps, but the one's for sale will work fine. For these small vises, you may find the 6" parallels are a bit unwieldy. I bought some 3" parallels from LMS (when they went on sale). For bigger stuff, just clamp to the table. Sometimes you need to use a sacrificial spacer, or you use 123 blocks as the spacer (with care).

I bought my toolmaker's vise and used it as a primary vise for about 5 months, while waiting for a Kurt DX4 to go on sale. The Kurt is easier to set up, but the toolmaker's vise has less jaw lift. I know, because I measured it.

When I bought mine, it did not have the slot on the side, so I milled them. I'd never try to do that again and to make it worse, I did it on the minimill. I actually tried an LMS 4" "precision" milling vise on my knee mill, but didn't like it and confirmed for me my preference for the 3" screwless vise.

The one really annoying thing about the screwless vise's tightening screw (yes, it actually does have a screw, SHCS) is that the locating pin kept dropping out of it's slot such that the jaw lost its "position". I added a spring under the screw head to keep the pin up in its locating slot. Pushing the screw head down releases it for repositioning, when you want it and not when you don't.

Rick

Attachments

Last edited:

- Joined

- Dec 18, 2019

- Messages

- 7,650

I took a different approach using a stud, and a custom nut. Machined the nut from 1144. Since it's a stud, I don't lose the locating pin as the stud stays secured. I use a stubby wrench to tighten it. The built-in flange holds the wrench if I need it to.I refer to this type of vise as "screwless" as that is how it was listed when I bought it and is the most common reference I've seen. I've been using the same 3" screwless vise for nearly 25 yrs, first on a minimill, then on an milldrill and now on a 2x26 knee mill. I do this partly because the machines I've had don't really have the capacity for larger vises but more so because I like how they work and their precision. One of the strongest advantages is that the moveable jaw do not spring, closing tighter and more parallel/perpendicular and I don't have to hammer on the parts as much to seat them snugly on parallels. In addition, it's footprint is much smaller and overall height is lower.

When I bought mine, it did not have the slot on the side, so I milled them. I'd never try to do that again and to make it worse, I did it on the minimill. I actually tried an LMS 4" "precision" milling vise on my knee mill, but didn't like it and confirmed for me my preference for the 3" screwless vise.

The one really annoying thing about the screwless vise's tightening screw (yes, it actually does have a screw, SHCS) is that the locating pin kept dropping out of it slot such that the jaw lost its "position". I added a spring under the screw head to keep the pin up in its locating slot. Pushing the screw head down releases it for repositioning, when you want it and not when you don't.

Rick

One last thing, use short hex head screws for the hold downs. Socket head cap screws will fill with swarf, ask me how I know.

One last thing I learned the hard way, use some sort of thick shims under the pivot point of the hold down, if you don't, you will be rewarded with little linear dents in the table. Even an aluminum shim will prevent that from happening.

- Joined

- Dec 21, 2018

- Messages

- 2,203

I've got a "Tool maker's" / Screwless 3" (2 7/8", 172mm) vice that I use as a vice in vice or on the rotary table. As it came it was a PIA to adjust & clamp. Shars #2016-4-25-194. I made a different pin and nut for it. Much better now. I think Stefan Gotswinter uses this type of vice on his mill.

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 8

- Views

- 688

- Replies

- 13

- Views

- 4K

- Replies

- 14

- Views

- 2K