- Joined

- Mar 22, 2013

- Messages

- 215

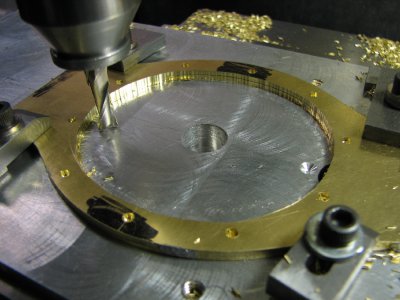

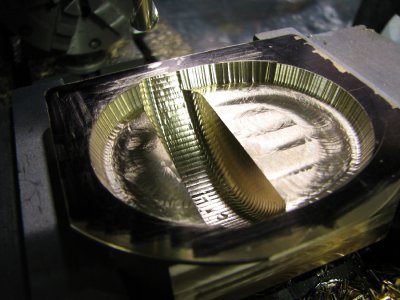

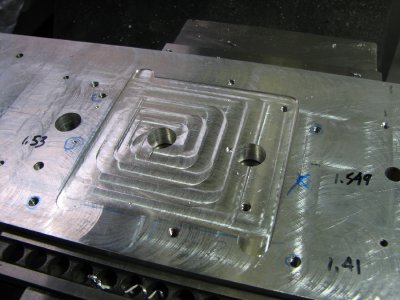

The next part would be the 2 spool halves. The spool is the part that houses the spider gears and onto which the ring gear attaches. These were mainly a turning job. There was a relief pocket cut on the inside where the spider gears fit. The spool also needed a cross reamed hole for the spider gear shaft and the tapped holes to mount the ring gear.

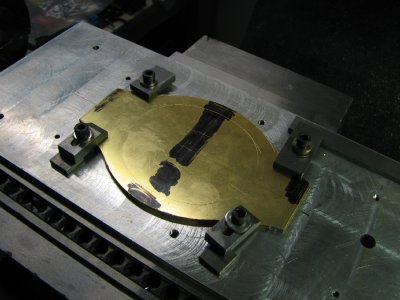

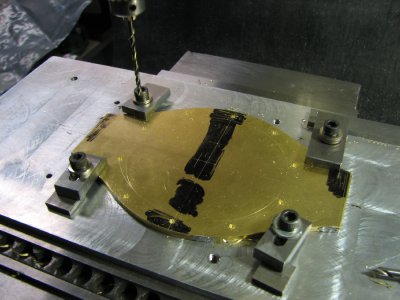

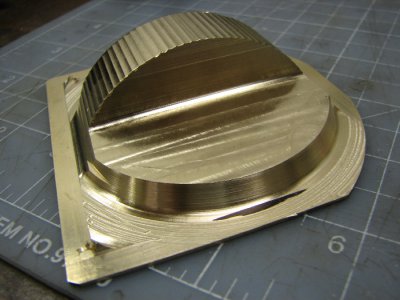

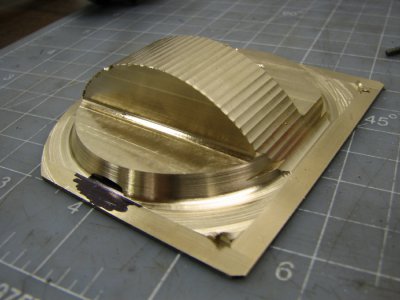

I had purchased a set of bevel gears that were a close fit to the required dimensions. They only came in brass and I didn't want brass against brass so I opted to make the smaller gears from steel, although with the amount of use they'll get I doubt that it would have mattered if they were all brass. I also purchased a piece of splined bushing stock. This was turned down, cut to length and pressed into the spider gears. These splined bushings will accept the ends of the axles when I get to that point.

gbritnell.

I had purchased a set of bevel gears that were a close fit to the required dimensions. They only came in brass and I didn't want brass against brass so I opted to make the smaller gears from steel, although with the amount of use they'll get I doubt that it would have mattered if they were all brass. I also purchased a piece of splined bushing stock. This was turned down, cut to length and pressed into the spider gears. These splined bushings will accept the ends of the axles when I get to that point.

gbritnell.