- Joined

- Dec 3, 2013

- Messages

- 1,849

The main issue is lack of documentation for us mere mortals. I guess that's how they sell "training" to further bloat the already outrages cost.

I can do the slots in a rotary mode, it just opens the top of the slot by 0.040" which is okay. I may do that if I cannot figure out the other or as Jim suggested, enter the radial moves manually into the g code.

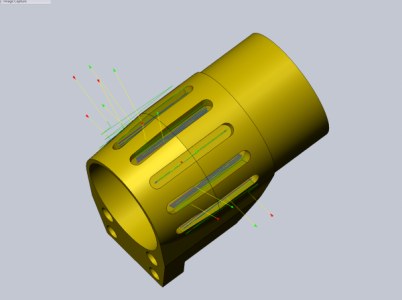

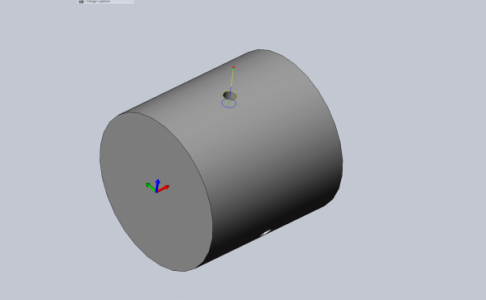

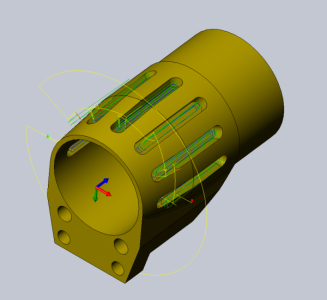

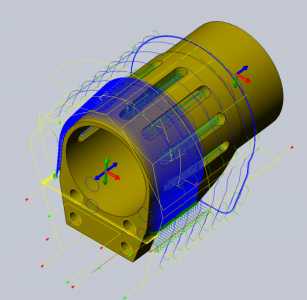

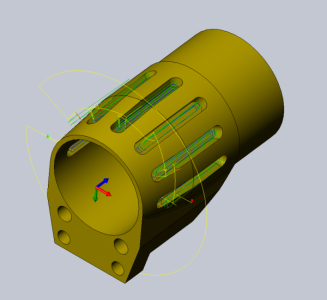

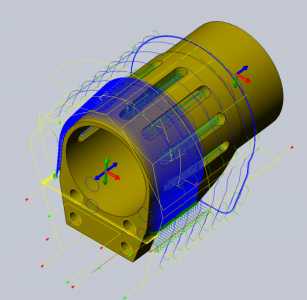

Here is the part with the radial tool paths for the slots and one with all the mill ops to do the part. A total of 7 milling ops with 2 setups. The main bore and front will be turned on the lathe first with the balance done on the mill.

I have some time before I need this part plus I need to finish the stepper motor mount for the rotary table and that will require a lathe which I won't have my new for another week.

I can do the slots in a rotary mode, it just opens the top of the slot by 0.040" which is okay. I may do that if I cannot figure out the other or as Jim suggested, enter the radial moves manually into the g code.

Here is the part with the radial tool paths for the slots and one with all the mill ops to do the part. A total of 7 milling ops with 2 setups. The main bore and front will be turned on the lathe first with the balance done on the mill.

I have some time before I need this part plus I need to finish the stepper motor mount for the rotary table and that will require a lathe which I won't have my new for another week.