I'm repowering an outdoor vacuum/chipper I made to an effectively unknown brand motor of the same size that I picked up cheap from PrincessAuto.

The old motor, a B&S 900 series, was working ok but the air filter just wasn't up to being able to handle the amount of dust the vacuum generates, and would plug up pretty quickly. I rebuilt it last year, but again had the same problem, and it's just not worth spending about 50% of the cost of a new engine in parts to rebuild it.

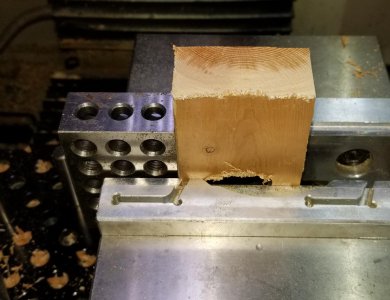

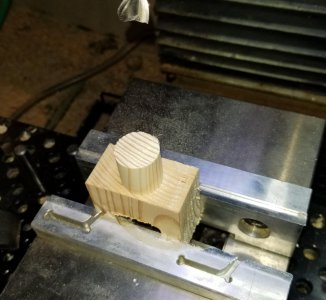

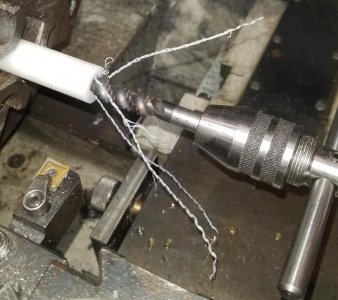

Today I worked on getting the impeller properly mounted on the crankshaft. The old crank is 1" OD, with a 1/4" keyway, about 3" long, and gets slightly larger near motor, and the impeller slides onto the crankshaft until it hits that slightly larger part, and a bolt going into the end of the crank holds it in place. The new crank is the same overall length, but it's 1" for most of the length, without a larger bit near the engine , the last 3/4" of the crank is reduced in diameter to 7/8", and has a 3/16" keyway.

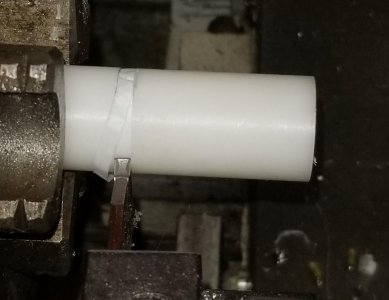

To make the impeller mount properly on the new crankshaft, I bought a 3/16-1/4 step key, and then made a spacer that goes over the end of the crankshaft, both to make that last 3/4" of the crank be 1", but also has an extra 1" of length to space the impeller the same distance from the engines mounting surface.

Pic of the spacer, installed:

View attachment 302598

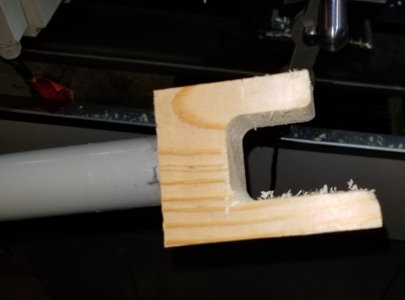

Also had to customize the gas tank a bit with a BFH so the chipper chute would clear it:

View attachment 302599

Still to do, it make a new liner for the blower housing. I previously made one from 16 gauge steel after wearing a large hole in the housing, and it's also worn through in a spot, so I'll make another one from a strip of 3" x 1/8" flat steel I bought. I'll also have to figure out how to get a larger air filter mounted onto the engine, to avoid another early death of the engine.

View attachment 302600