- Joined

- Dec 22, 2015

- Messages

- 561

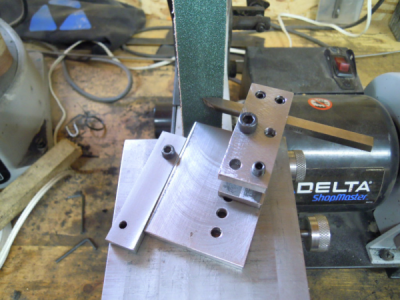

It was time to sharpen some bandsaw blades for my Norwood sawmill. It is a monotonous job, requiring me to hand crank the sharpener to advance the blade from one tooth to the next and I had 10 blades to sharpen with 165 teeth each (at roughly 20 minutes per blade if all goes well). I decided it was time to automate the process. I had some parts from a recent treadmill salvage and used the driven plastic wheel and drive belt. But needed a motor and drive pulley. I got a surplus motor from PA for $20 and made a drive wheel pulley to fit the output shaft. I had to check Machinery's Handbook to get the specs on the flat belt groove angles, spacing and depth. Then made a small cutting tool for the job using my Harold Hall simple grinding rest and small tool holder. I love this thing. Thanks Harold.

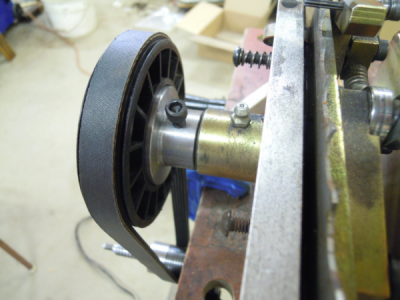

Drive pulley and motor.

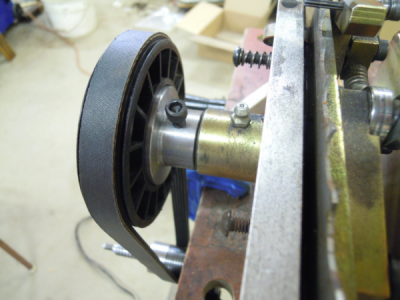

The Driven pulley and the adapter I made to fit the inside of the plastic pulley and the drive shaft of the sharpener. The plastic pulley was a press fit and I surprisingly got it to work.

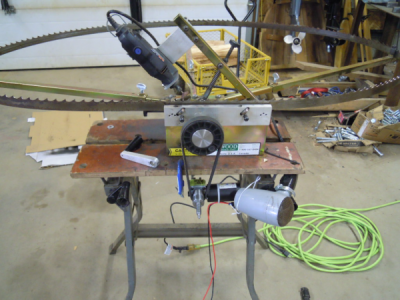

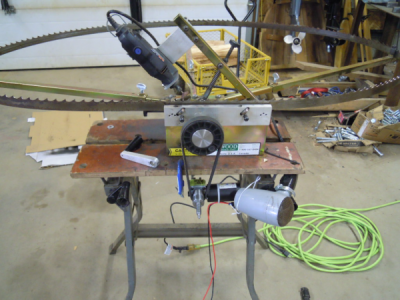

The overall setup. Note the handle sitting on the bench. This will no longer be needed. I found the motor started getting warm so mounted a hair drier (that I use for my forge) to the table, to cool it down.

This thing worked awesome. Should have done this years ago.

Wish I could insert a video of it running. It's cool to see the sparks fly.

Drive pulley and motor.

The Driven pulley and the adapter I made to fit the inside of the plastic pulley and the drive shaft of the sharpener. The plastic pulley was a press fit and I surprisingly got it to work.

The overall setup. Note the handle sitting on the bench. This will no longer be needed. I found the motor started getting warm so mounted a hair drier (that I use for my forge) to the table, to cool it down.

This thing worked awesome. Should have done this years ago.

Wish I could insert a video of it running. It's cool to see the sparks fly.