- Joined

- Mar 25, 2013

- Messages

- 5,129

Attachments

Last edited:

Why is it all apart? It looked good in the previous photos.Thanks Mark. That's what I need to know!

The whole dang thing fell apart...

R

Hey, I was just kidding around! I pulled it apart to remove the layout fluid and sand the surfaces prior to final assembly. I wish I had a better way to finish aluminum. Hand sanding is a pain and you can never get out most of the scratches. I just went over it lightly to remove the superficial scratches and dirt. Anyone have any good ideas on finishing? Has anyone ever used a drum sander like they do for wood? How about a hand held orbital sander?+1 on what happened. It did look good in the photos. With it put together I figured out why I was thinking the angle iron was in the way For some reason I thought it was a three wheel version.

Defiantly want to know what happened.

No....no..... An orbital sander will make tiny circles all over the part and it will look like crap. I hand sand in a straight line with 320 grit to clean and polish the same way with 400 after. Then you can use a buffer and aluminum polish to make a mirror finish.Hey, I was just kidding around! I pulled it apart to remove the layout fluid and sand the surfaces prior to final assembly. I wish I had a better way to finish aluminum. Hand sanding is a pain and you can never get out most of the scratches. I just went over it lightly to remove the superficial scratches and dirt. Anyone have any good ideas on finishing? Has anyone ever used a drum sander like they do for wood? How about a hand held orbital sander?

This is only a 48". The angle grinder would be in the way if I was making a 72" with 3 wheels for sure.

R

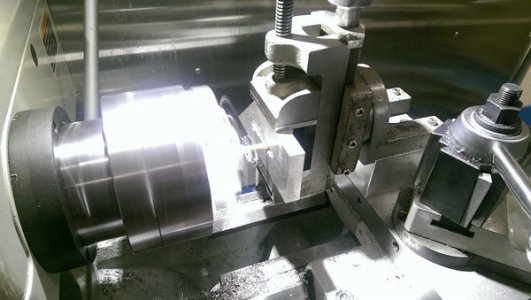

If the platen gets too hot it is too close to the belt. It should barely touch the belt but be parralell with it. What is that round thing in front of the belt?