I was working on the electronics side of this, got the motor hooked up to the control board to do some testing and code debugging. Had to fix a few code issues, but the DC motor turns both forward and reverse. But it turns pretty rough, bad enough that I'm not going to be able to do the needed tuning on the two Parker DC power supplies.

For those into technical details, the Parker units are meant for powering DC motors, so they have some control functions built in. Somewhat like a VFD, you give it a low voltage signal which it translate to RPM (armature voltage) for one, and field current for the other. DC motors being somewhat odd, you start out with full field current, and increase the armature voltage to (roughly) increase the RPM. When you reach peak rated voltage on the armature, you are not yet at the motor rated maximum RPM. To increase the RPM further, you

decrease the field current. Interestingly, some DC motors, especially if unloaded, will self-destruct in overspeed if you decrease the field current to zero. Which could happen if the field circuit or wiring fails.

The Parker 514 is a full armature controller, and understands how to monitor the current and voltage of the armature and control it appropriately to get desired RPM even with a changing load, and will provide braking (allowing current to flow back to the line) if the RPM gets dialed back. It does take some tuning, it is essentially an analog PID controller, so various gain parameters need to be set. But it doesn't know how to coordintate this with the 507 field controller. Some people just use two separate inputs (pots) to control them separately, and it is up to the operator to know how to fiddle with two knobs to get the desired RPM.

I decided to build a digital controller front end that uses one knob to set the RPM I want, and that microcontroller figures out how to get there from where ever it is now. All good in theory, but of course now three devices (microcontroller and two Parker DC supplies) that need to coordinate correctly. Or really, I have to program the microcontroller correctly and tune the Parker's correctly. But wait, there is a fourth player. The motor itself. This motor needs some help, as the commutator is not in great shape. With a bad commutator and brushes making less than good contact, the motor struggles.

So the DC motor needs to come apart. Sort of thought that would be a good idea anyway, new bearings and brushes was on the list. Additionally, I'm going to need to turn the commutator, as in put in on a lathe and take a couple thou off to get a nice, round, even surface for best brush contact and life. After turning the commutator, the mica insulation between the commutator bars needs to be undercut a bit, as otherwise the mica will not allow good brush to copper contact.

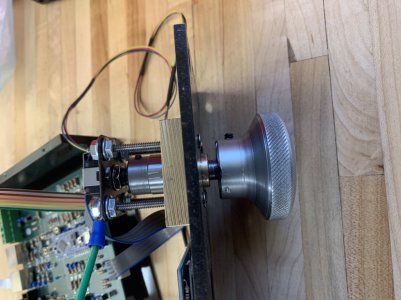

My workbench is a bit full of projects (pieces) so I've decided to get the apron reassembled before tearing into the DC motor. So the apron is going back together. I replaced the bearings that ride on the underside of the ways, and the thrust bearings on either side of the feed worm. The other bearings seem to be in pretty good shape. The pinion gear that rides on the bed rack is a bit more worn then I'd like but it isn't so bad that it won't engage. I replaced the filter on the oil pump and cleaned that out. This apron also has part of the ELSR (electronic lead screw reverse) which is really just a motor shut off. That mechanism had one of the fittings commonly used for grease but intended for oil, so that mechanism was a mess of old solidified grease. Picture is from a day or two ago, it is almost completely back together now, just waiting for a coat of touch up paint to dry enough to move it off the bench. I have the QCGB ready to go back into the lathe too, so need to do that. Shop is getting crowded with parts. Then I'll tackle the motor. Keep your fingers crossed that I'm able to clean up the commutator, and motor in general. Otherwise .... VFD and oversized induction motor will be in this lathe's future.