I'm glad you are enjoying this project because I'm about burnt out on it. I have done this type of work to quite a few other machines in my shop but it has never been at this pace. It took me 4 years to finish the Burke #4 mill and I think the fastest I have ever gone through a machine was 3 months for a DoAll band saw. I have a very lucrative job pending that requires this lathe and that is why I have been going full tilt on it, if I finish it this week it will have been about a 6 week job but I don't want to jinx myself.

I got some young guys from my day job to come over at lunch today and get the apron mounted on the carriage. It took 3 young guys and myself to get it up into place and bolted on to the carriage as the thing weighs about 250#s.

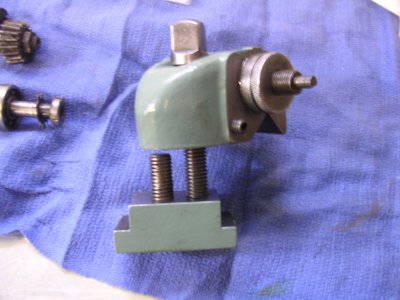

I got another batch of parts painted and got some more of the taper attachment mounted.

I really didn't want to get back into stripping paint and filler but the tailstock was just in way too bad of shape not to strip it down and do it right, I have way too much time and labor invested in this lathe to start cutting corners at the end of the job. I have applied one coat of stripper and I think that I can sand the rest rest of it to the point that I can start applying filler so the paint will look nice.

I go back to work tomorrow so the compound will go with me and get put in the parts washer. Once the tailstock and compound are done, that should be about it for the lathe. The only thing left to do will be to get the electric control box done and figure out how I'm going to run power to the lathe after I figure out where I'm gong to put the lathe. I have moved this lathe twice since I brought it home and once I figure out where to put it, I don't want to move it again until I move out of NJ.