- Joined

- Feb 25, 2014

- Messages

- 349

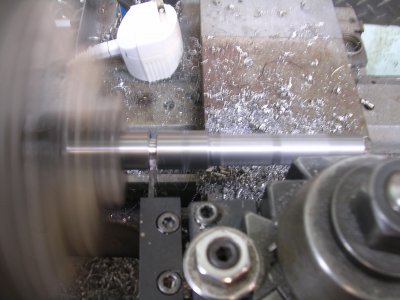

Well it took me a lot longer to get the saddle all cleaned up and painted. I think I spent the better part of 3 days working on it. The bare saddle casting weighs a little over 200#s and I needed a way to work on the whole thing without having to turn it over repeatedly. I bolted 2 pieces of 3/16" flat stock to the bottom of it, stood it up on end, and welded the flat stock to the table. Having it upright where I could work on both sides at the same time made things so much easier.

I have it all cleaned up, painted and ready to back on the ways. The oil galleries that feed the grooves in the saddle bearings had felt wicks in them and they were pretty much shot so I ordered some felt cord from McMaster-Carr and it should be here tomorrow. I'll recruit some help from one of the young guys at work and have him help me lift the saddle back on to the ways.

Next up is tearing into the apron and seeing what it needs, I'm sure that will take a few days to get done.

I have it all cleaned up, painted and ready to back on the ways. The oil galleries that feed the grooves in the saddle bearings had felt wicks in them and they were pretty much shot so I ordered some felt cord from McMaster-Carr and it should be here tomorrow. I'll recruit some help from one of the young guys at work and have him help me lift the saddle back on to the ways.

Next up is tearing into the apron and seeing what it needs, I'm sure that will take a few days to get done.