-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

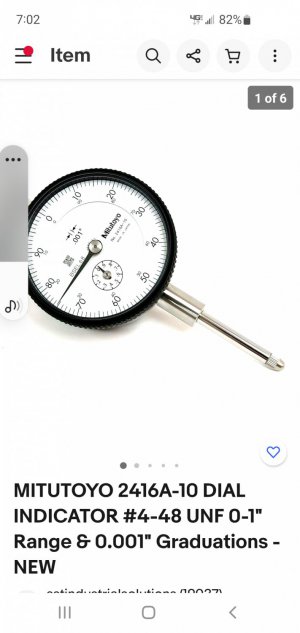

[How-To] Zeroing coarse indicator dial

- Thread starter dml66

- Start date

- Joined

- Feb 5, 2018

- Messages

- 637

Does it move at all?

Joe

Joe

- Joined

- Feb 5, 2018

- Messages

- 637

The indicator is fully extended in the picture, it's at it's rest position. Rotating the outside ring dial is just aligning the rest position with zero, it doesn't move the pointers. I did look at another indicator I have, the coarse dial doesn't read zero at rest either, maybe it's just how it is.

The more I think about it, one is a relative indicator, the other an absolute. I need to reprogram my brain, lol.

The more I think about it, one is a relative indicator, the other an absolute. I need to reprogram my brain, lol.

- Joined

- Feb 5, 2018

- Messages

- 637

Press the plunger in about. 002" and I bet it lines right up to the 5. Then it will make 5 more revolutions and bottom out on travel.

Joe

Joe

- Joined

- Feb 26, 2014

- Messages

- 257

The hands are simply pressed on, remove the bezel and glass, gently pop the hand off with a pair of fine screwdrivers and put it back in the position you want.

Thanks all for the help. The entire gage is like a mirror image. Since it's designed to measure hole diameter, the more the stem is pressed in, the smaller the hole, unlike measuring runout. When used as a go no-go type gage, it's easy for me to adapt to. When using it while making a hole to see if I'm close is where I struggled a bit. I'll just use a pin gage to start the hole and reserve this tool for the last thou.