Worthless vices story for my X2 mill

When I first bought my mill I bought a cheap 80mm vise to learn how to use the mill.

As you can imagine it was far from perfect for precision work and as I was feeling more and more comfortable in using the mill I decided to buy a PRESISION VICE to be able to do some more presision work.

Mr e-bay helped me to find a vise within my budget (80 GBP) and I ordered it.

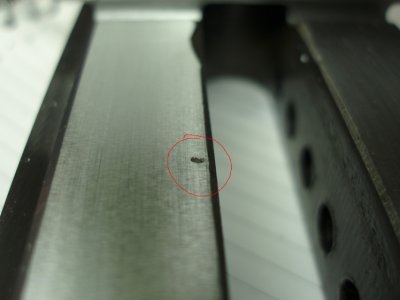

When the vise arrived I noticed a few things I was not happy with:

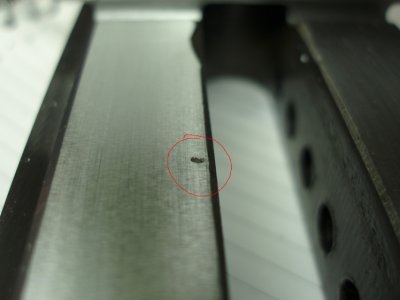

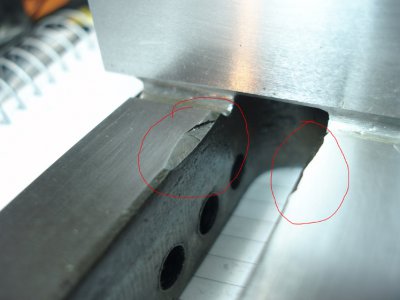

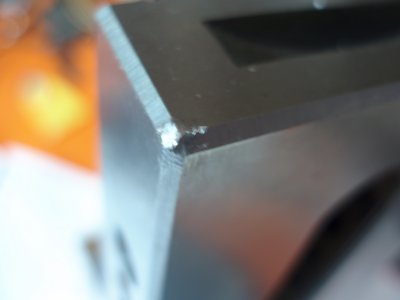

A. Marks

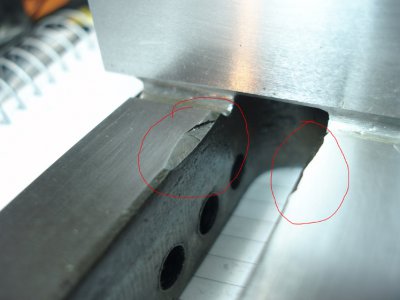

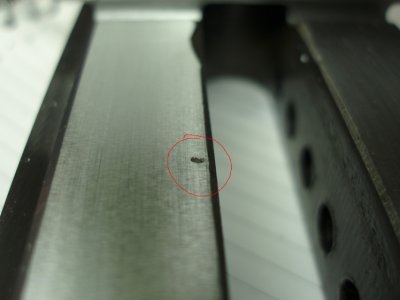

B. Holes on the body

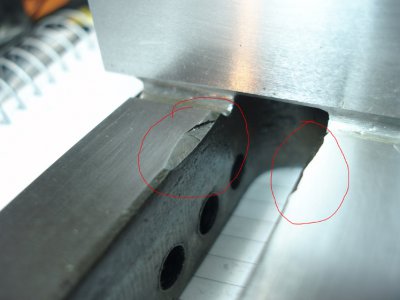

B. Holes on the body

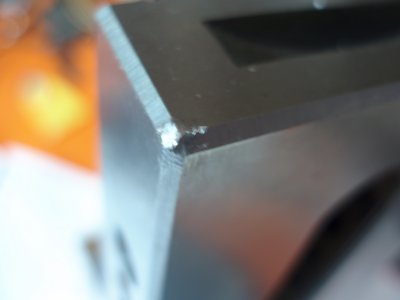

C. Missing/broken body parts

C. Missing/broken body parts

D. Scratches everywhere

D. Scratches everywhere

E. Pin was bent and in bad shape

E. Pin was bent and in bad shape

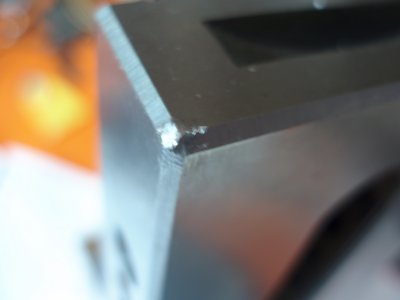

F. Drop marks

F. Drop marks

I was so frustrated with the tool I asked the seller to replace it. He agreed under the condition to send back the vise. When I tried to do so I found out that the postage would be half the value of the vise. I felt it was not worth it to pay another 40 pounds for it so I asked the seller to refund 50% of it's value and I would keep the vise.

He agreed and I have a vise I donot like and I never used.

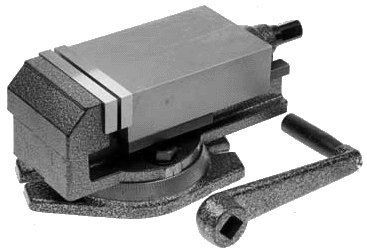

PART B KURT STYLE VISE

Next I put some rectification work on my first 80mm vise and now I can do work on the mill in a satisfactory level

BUT...

I was not totaly happy with it and recently I decided to buy a Kurt style vise for my mill.

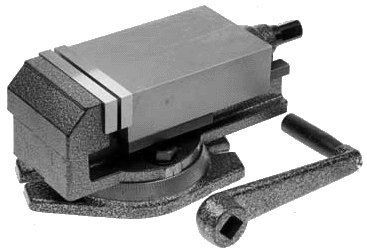

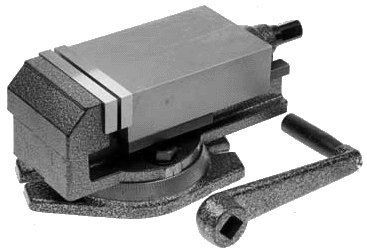

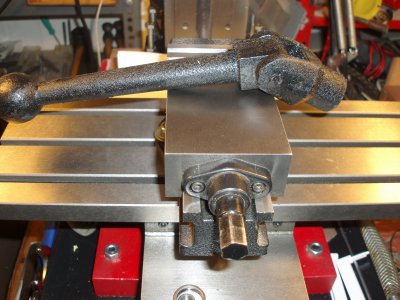

I chose I reputable seller (Chronos.ltd.uk) and I ordered a cheap (in comparison to real KURT) Taiwan-made Vertex VA-4 (Four inch) vise.

I thought a 100mm vise will fit nicely on my mini mill....

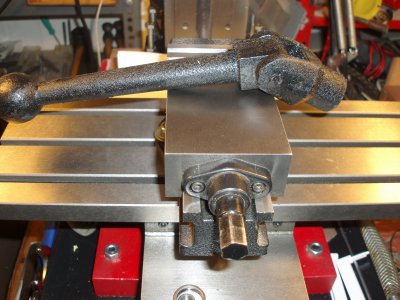

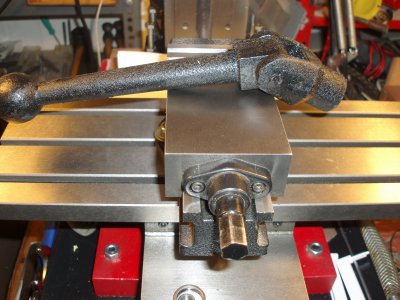

When the box arrived I was shocked by the size of it.

It had the same size to my mill table!!!

When I opened the box and took the handle out I froze!!

It was half the size of the mill table!

When I put the vice on the mill table I felt a complete idiot.

Even without the base It was a monster

Who will imagine that 20 mm (0.8") will make that difference!

New vise is nearly double the size of the old one!!!!

As I like the vise, from the looks of it anyway, I made an important decision: To keep the vise and change the mill for a bigger one.

That also means that I need a bigger shop and deeper pockets that I have not got at the moment!

Until then I remain with two vises that are worthless tools for me.

Thanks for your understanding!

I had to confess it to somebody.

As you can imagine my wife is not the "understanding soul" that I wish to be, so she knows nothing on that!!!

Petros