- Joined

- Apr 12, 2011

- Messages

- 3,480

Hi

my post has gone ?????

Yes it is. Please read this for an explanation.

Site Crash

Sorry for the inconvenience.

Hi

my post has gone ?????

Hi Andrew

I live in Droylsden Manchester, are you far away.

Jeff

Hi ody, When you are doing the blockwork, it is normal to build the corners (some call them quoins) first, go up 3 courses at each corner, building with the square and level, then fill in between using your builders line string. If you dont have a square you can make one out of timber. Fix it together with one screw at the corner then measure 300mm down one arm, mark it and measure 400mm down the other arm. when the measured diagonal between the two marks is 500mm it is square! It's looking really good so far!

Phil

East Yorks.

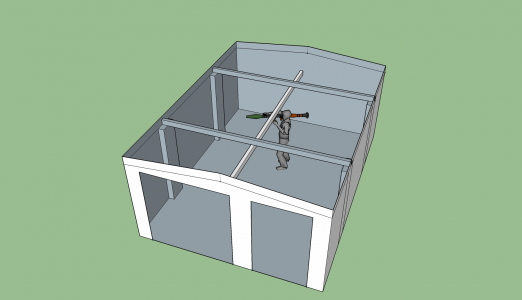

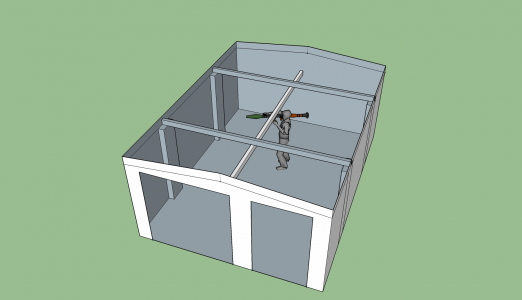

I'm thinking of using 126x76 universal beam which will span 4.1meters ish .. I've had a go at trying to figure out the load capacity but these bending moments and what not are beyond me .. if anyone has any ideas on how to figure out what the rough weight capacity would be I'd appreciate it .. otherwise I'll make sure the beams don't bend two much when in use

The long beam running perpendicular to the two main beams will be free to run side to side and a trolley on that beam will mean I'll have full X and Y travel across pretty much the entire span of the workshop.

.