- Joined

- Feb 8, 2014

- Messages

- 11,144

Don't get too hung on the clamp kit, anything that kinda looks like a clamp will work. Even a heavy washer, or a piece of metal with a hole in it. You are only limited by your imagination, there is no right or wrong way to do this. It is only important that it gets the job done.

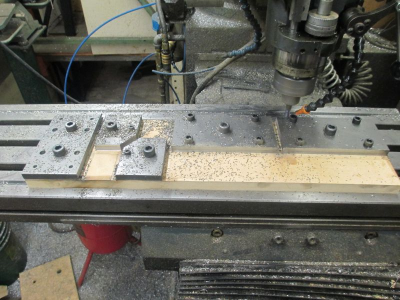

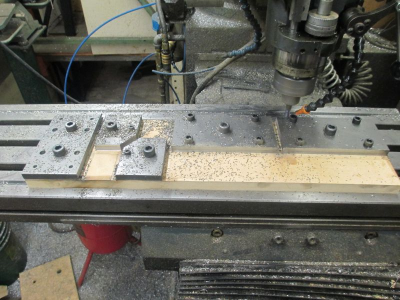

Here is one method I use, the large bolts are screwed into T nuts, the smaller ones are threaded into the 3/4 MDF under the parts. Just drilled & tapped the MDF for the 3/8 cap screws.

Just make sure the bolts don't bottom out in the T slots, that breaks tables.

Here is one method I use, the large bolts are screwed into T nuts, the smaller ones are threaded into the 3/4 MDF under the parts. Just drilled & tapped the MDF for the 3/8 cap screws.

Just make sure the bolts don't bottom out in the T slots, that breaks tables.