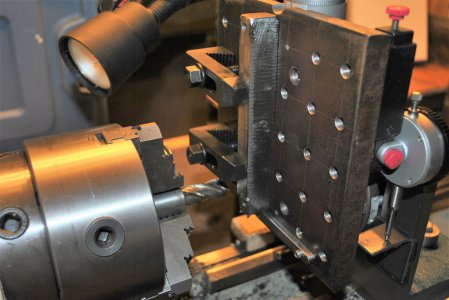

For some years I did my milling on the mill segment of a Grizzly G0516, basically their version of a Sieg X2. This usually involved small work pieces held in a 3" screwless vise. Recently I've started working with a Little Machine Shop 5550 mill, a version of a Sieg X2.7. One of the motivations for the mill upgrade was to be able to work with larger pieces.

Right now we have a series of 6" x 6" x 5/8" aluminum plates that we need to cut some slots in. Won't fit in my little vise, so I thought we'd clamp it directly to the table. The problem was that, using the bolts and blocks I could find in my clamping kit, the bolts stuck up too high for the end mills to be able to reach the work piece.

So some questions.

First, if I'm having trouble getting this done with the clamping kit, am I just thinking this through the wrong way? The kit is a pretty standard one from LMS (https://littlemachineshop.com/products/product_view.php?ProductID=1144).

Second, are there a good low-profile clamps I can look for to hold down work pieces in the size range mentioned?

Third, any suggestions on a vise I might look at for this size of work piece that wouldn't completely wreck my budget?

And finally, anything good to look at in the way of videos, articles etc that might get me more up to speed on work-holding in this size range?

Right now we have a series of 6" x 6" x 5/8" aluminum plates that we need to cut some slots in. Won't fit in my little vise, so I thought we'd clamp it directly to the table. The problem was that, using the bolts and blocks I could find in my clamping kit, the bolts stuck up too high for the end mills to be able to reach the work piece.

So some questions.

First, if I'm having trouble getting this done with the clamping kit, am I just thinking this through the wrong way? The kit is a pretty standard one from LMS (https://littlemachineshop.com/products/product_view.php?ProductID=1144).

Second, are there a good low-profile clamps I can look for to hold down work pieces in the size range mentioned?

Third, any suggestions on a vise I might look at for this size of work piece that wouldn't completely wreck my budget?

And finally, anything good to look at in the way of videos, articles etc that might get me more up to speed on work-holding in this size range?