- Joined

- Dec 18, 2019

- Messages

- 6,527

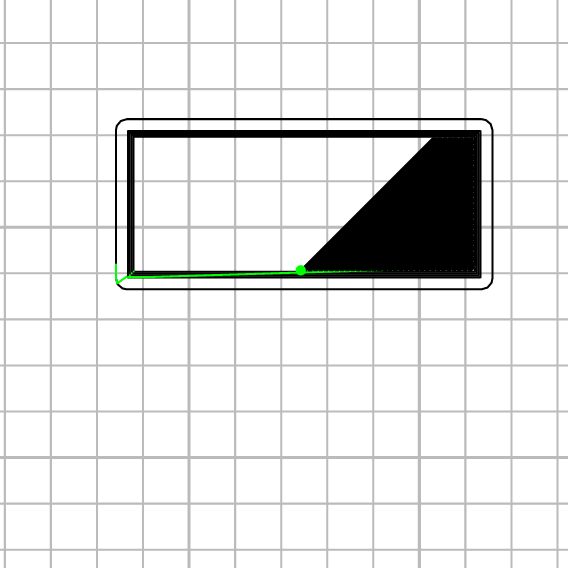

Being new to all this, I have to ask. Is this outline just a thing that happens? There's an outline around the part. Is this for a raft or brim? I have neither selected, so why the rounded ring around the part? This is an Octopi g-code renderer for this layer. There is an actual ring around the part, a few layers thick.