Hello,

Need a part made, I don't have the proper tools. Can anyone recommend someone willing to help?

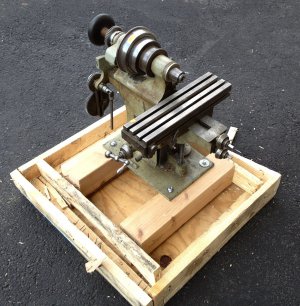

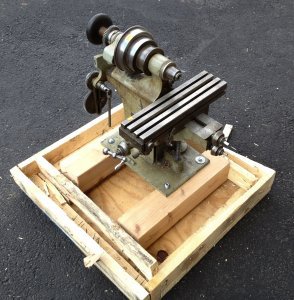

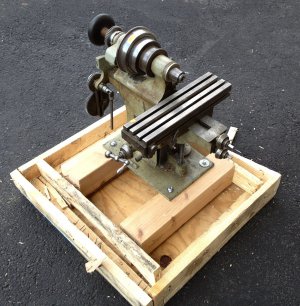

Bought a little Hardinge miller the other day .... was damaged when they put it in the box for shipping!

Here is a picture of how it arrived.

As you can see they caught the lower knee vertical adjustment when putting in the shipping box.

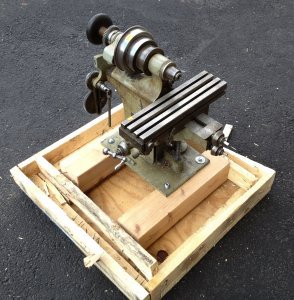

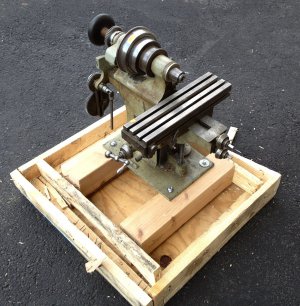

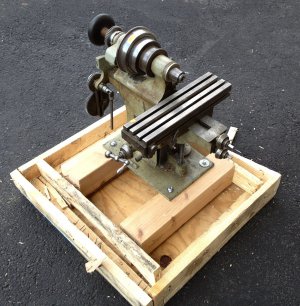

Could not get it apart without trying to straighten .... broke it off of course.

Threads are somewhat distorted, but here is what I have to deal with now.

Have an extra screw with the right threads, but will need to be machined, sleeved and keyed to work. Or the other option is to somehow reattach the the broken end and repair the threads. Can any one help with this project? Thanks!

Need a part made, I don't have the proper tools. Can anyone recommend someone willing to help?

Bought a little Hardinge miller the other day .... was damaged when they put it in the box for shipping!

Here is a picture of how it arrived.

As you can see they caught the lower knee vertical adjustment when putting in the shipping box.

Could not get it apart without trying to straighten .... broke it off of course.

Threads are somewhat distorted, but here is what I have to deal with now.

Have an extra screw with the right threads, but will need to be machined, sleeved and keyed to work. Or the other option is to somehow reattach the the broken end and repair the threads. Can any one help with this project? Thanks!