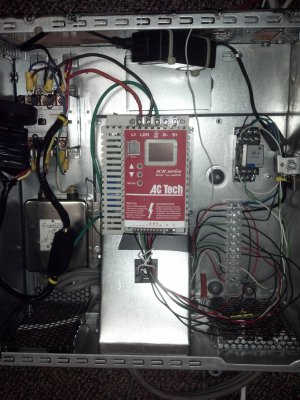

First off, I think mounting the VFD in an enclosure is a good idea. Most of these smaller VFDs have a plastic cover which has an IP20 rating. This means the openings are small enough that you cannot get your fingers on high voltage, but little or no protection against dust, flying chips, oil mist, etc. If your shop is like mine, the distance from one machine to the next is small enough that the drive could be contaminated when another machine is in operation. The VFD manufacturer thinks you are going to mount the VFD in a large panel with a bunch of other components, and probably with provisions for cooling.

One consideration with putting the VFD in a small enclosure is cooling. Wolf Automation in Chicago publishes a catalog page with their recommended minimum dimensions of panels for the drives that they sell. For a 1 HP TECO drive, they say min dims are 12"H x 10"W x 8" deep, but their chart is for metal enclosures. A plastic enclosure will not dissipate heat as fast as metal. It may be necessary to oversize the box, or to include some ventilation openings - which seems counter productive. I have a 3 HP TECO VFD that I want to mount in an enclosure. I found a 12x9x8 plastic box at a surplus dealer - brand new with no holes. It has a NEMA 4X rating for outdoor exposure, with a gasketed door with SS hinges and latches. Before I butcher it up, I am running an experiment. I fabricated a simple enclosure around the drive made up of a 2 gallon plastic bottle which has about the same dimensions as the plastic enclosure. A Stanley knife and some duct tape was used to get access for the wires and controls. I use my calibrated hand to sense the temp inside test enclosure. This test enclosure has thinner wall thicknesses than the actual NEMA model, but I figure it will get me a good idea of expected temp range. So far I have only found the air in the test enclosure to be around 100F after an hour of running the lathe. I need to find a large diameter piece of scrap steel to really load up the motor and check the temp rise under high load.

I like your idea of a window on the front to view Hz, and function.

Terry S.