-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is a good size and possible brand vise for the Smithy 3-1

- Thread starter mac1911

- Start date

- Joined

- Sep 10, 2022

- Messages

- 934

This is just me speaking. That vise is more of a drill press vise. I like my mill vises to be low profile and very stable. I am not familiar with the table size of your Smithy. I would opt for a good quality 4” vise. Maybe even a 3” if you work with smaller parts. You can always use a sine bar to set angles when needed. I would much prefer solid and low profile to maximize working area and clamping force.

Cutting oil is my blood.

Cutting oil is my blood.

- Joined

- Apr 30, 2015

- Messages

- 11,354

3" might be the limit with the size of the table it has, I've seen pictures of it and you may have rigidity issues with something larger/taller

- Joined

- Sep 10, 2022

- Messages

- 934

4” from Shars is likely as good as you need for your machine. I have one and am happy with it.

John

Just looked $102 for a 4” Kurt type. Not bad.

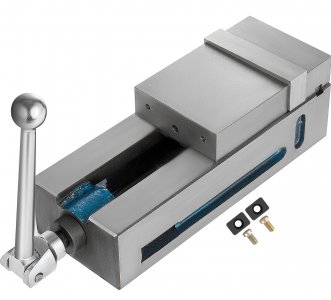

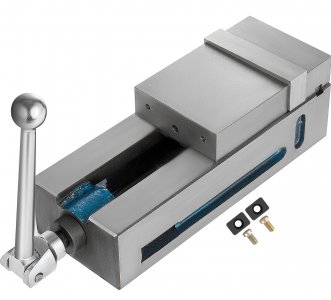

4'' x 3.93" Lock Down Precision Milling Machine Vise

Cutting oil is my blood.

When I had a Smithy the best thing I found was a 3" 'screwless' grinding vise - I think I even got it from Smithy. My Smithy has been gone 20+ years, but I still have, and use, that vise. The vise that comes with a Smithy is junk - it's completely inadequate for milling and I can see a lot of people blaming themselves while it's the work walking all over the place.

GsT

GsT

Thanks , its going to be a while before I egen get around to the milling head , im working my way around the machine looking for loose/worn/missing parts. Its amazing this poor thing worked at all.

I just got around to the motor and belt drive system loose, bent, argh

loose, bent, argh

What I need is “Factory Reset” button!

Ive mad a few cuts with the tooling that came with it and its , meh. I dont think there was a sharp tool in the box.

Oh and out of no where the clutch started disengaging on very light cuts? I will get there.

My big hurdle is the small blocks of time I have to get to it.

Running on generator and busy with everything else .

I just got around to the motor and belt drive system

What I need is “Factory Reset” button!

Ive mad a few cuts with the tooling that came with it and its , meh. I dont think there was a sharp tool in the box.

Oh and out of no where the clutch started disengaging on very light cuts? I will get there.

My big hurdle is the small blocks of time I have to get to it.

Running on generator and busy with everything else .

Last edited:

- Joined

- May 27, 2016

- Messages

- 3,479

Hi @mac1911

The vise in your picture will only disappoint you in the end. Your milling vise has to have some important features. You do not need to invest in a super-expensive Kurt or Orange Vise Co. product to get there. With a little clean-up, you can get 100m wide precision vises for $150 to $200.

Look for one which is square enough to be mounted on its side. The "moving" jaw needs the clamping screw to be pulling "downwards" when tightening. Check out some low-cost vises that look like they are the real deal.

_

_

Or .. spend a fortune on Orange!

These can be trammed with a indicator to line up to your machine ways. I am not sure the vise in your picture is up to that.

The vise in your picture will only disappoint you in the end. Your milling vise has to have some important features. You do not need to invest in a super-expensive Kurt or Orange Vise Co. product to get there. With a little clean-up, you can get 100m wide precision vises for $150 to $200.

Look for one which is square enough to be mounted on its side. The "moving" jaw needs the clamping screw to be pulling "downwards" when tightening. Check out some low-cost vises that look like they are the real deal.

_

_

Or .. spend a fortune on Orange!

These can be trammed with a indicator to line up to your machine ways. I am not sure the vise in your picture is up to that.

The Table is 6” wide 16” long with 7/16 T slots.This is just me speaking. That vise is more of a drill press vise. I like my mill vises to be low profile and very stable. I am not familiar with the table size of your Smithy. I would opt for a good quality 4” vise. Maybe even a 3” if you work with smaller parts. You can always use a sine bar to set angles when needed. I would much prefer solid and low profile to maximize working area and clamping force.

Cutting oil is my blood.

Attachments

- Joined

- Dec 18, 2019

- Messages

- 6,492

I bought this vise, from Little Machine Shop. https://littlemachineshop.com/products/product_view.php?ProductID=4871&category=

Very pleased with mine. You can buy the Z-clamps from LMS, or you can make your own vise holders like I did. Tool makers vises have very low deflection or jaw lift. That means your part stays flat and level when you tighten the jaws. Helps you make better parts.

If it helps at all, here's my thread on it. https://www.hobby-machinist.com/threads/making-some-screw-less-vise-hold-downs.90024/

Very pleased with mine. You can buy the Z-clamps from LMS, or you can make your own vise holders like I did. Tool makers vises have very low deflection or jaw lift. That means your part stays flat and level when you tighten the jaws. Helps you make better parts.

If it helps at all, here's my thread on it. https://www.hobby-machinist.com/threads/making-some-screw-less-vise-hold-downs.90024/