-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What goes on in my shop

- Thread starter vapremac

- Start date

- Joined

- Feb 17, 2013

- Messages

- 314

Yes I think maybe it was time to share. You do some beautiful precision work and must use a surface grinder to get that degree of finish. A surface grinder and MIG welder are the last 2 items on my wish list - the shaper came yesterday. Do you do it full time or as as a side job?

Thanks for sharing,

Michael

Thanks for sharing,

Michael

Thanks everyone for the kind words !

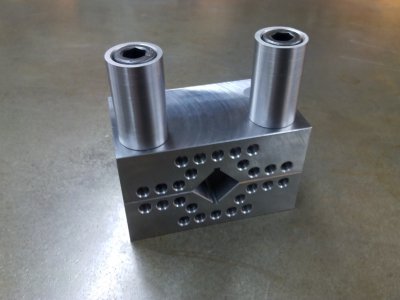

Valleyboy - Yes , I make my living from my machine shop .Always been a job shop but the

tooling I manufacture is fast becoming a large core of my business.

I have a mig welder but rarely use it .Tig, now that's another story my gas

supplier loves me.

12bolts. - Given what this tools purpose is I maintain as tight a tolerance that I possibly

can and still function silky smooth. As for the jig pins they are a snug push/pull

fit.

William

Valleyboy - Yes , I make my living from my machine shop .Always been a job shop but the

tooling I manufacture is fast becoming a large core of my business.

I have a mig welder but rarely use it .Tig, now that's another story my gas

supplier loves me.

12bolts. - Given what this tools purpose is I maintain as tight a tolerance that I possibly

can and still function silky smooth. As for the jig pins they are a snug push/pull

fit.

William

- Joined

- Apr 1, 2013

- Messages

- 1,142

William, Man I could not have come closer to ripping of you design even if I had seen it. Wow!! The whole great minds thing comes to mind. Yours is much nicer though. I do like the pins on top. How deap did you dill the holes for the dowl rods? Thanks for sharing your photos that does take it to enother level. Mark

- Joined

- Mar 10, 2013

- Messages

- 1,428

William--thanks for sharing some super nice pictures of your superb quality work--Dave

- Joined

- Nov 16, 2012

- Messages

- 5,596

Really nice work... I've got a CNC job coming-up in a few months to make a holding fixture that has a dedicated purpose inside of another machine. The holding area has an oblong shape. The tolerances won't need to be quite what yours looks to be but, it's a similar part and about the same size. It's a part of an automated mechanism and will need to be in Rockwell 55 range. Can't wait to start on this.

In any event, really nice looking work and thank you for showing us... We all like looking at these things.

Ray

In any event, really nice looking work and thank you for showing us... We all like looking at these things.

Ray