Uncle buck.... Think of it this way.

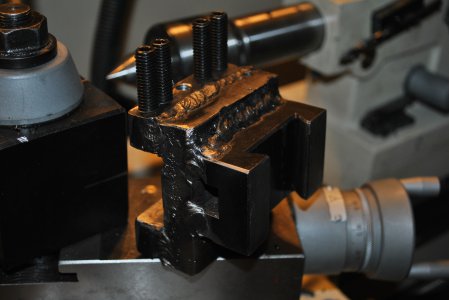

If the tool holder shift's .005" at the holder, How much did it move at the business end of a 5" boring bar? The correct answer is " Too much."

When the bars shift like that is when you chip the cutter, crack the insert and ruin the cut and or dimension.

When I was 18-22 years old I bought all kinds of low cost tooling. It was not long after that I started replacing it all with better stuff. I look back and think of how much money I wasted having to re-buy things. My new motto is " I am to poor to buy cheap things."

Spend the extra bucks on a wedge tool post.... That way you can never wish you had bought it instead.

If the tool holder shift's .005" at the holder, How much did it move at the business end of a 5" boring bar? The correct answer is " Too much."

When the bars shift like that is when you chip the cutter, crack the insert and ruin the cut and or dimension.

When I was 18-22 years old I bought all kinds of low cost tooling. It was not long after that I started replacing it all with better stuff. I look back and think of how much money I wasted having to re-buy things. My new motto is " I am to poor to buy cheap things."

Spend the extra bucks on a wedge tool post.... That way you can never wish you had bought it instead.