- Joined

- Jun 29, 2014

- Messages

- 197

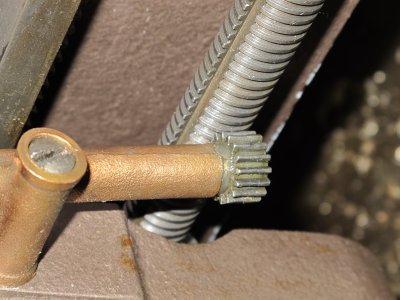

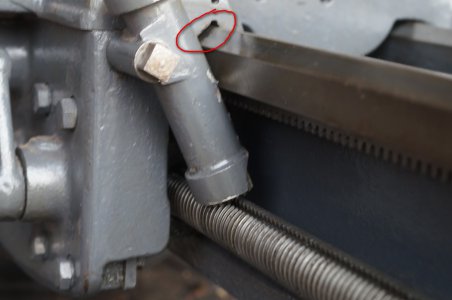

The more I fix the more I find other stuff to fix or be confused about. I finally got my motor wired so I have forward and reverse by flipping a switch with a separate on off switch. While checking things out a little more I installed the "thread dial". Something is wrong because it wants to climb over the "lead screw" and that is not a good thing at all. The dial I have is approximately 3 5/16" in total length. It has sixteen teeth, but the teeth seem too narrow for the lead screw threads. Is this the correct "thread dial" for my machine or should it be longer so it doesn't "climb" on top of the lead screw? Any suggestions would be greatly appreciated.

The more I fix the more I find other stuff to fix or be confused about. I finally got my motor wired so I have forward and reverse by flipping a switch with a separate on off switch. While checking things out a little more I installed the "thread dial". Something is wrong because it wants to climb over the "lead screw" and that is not a good thing at all. The dial I have is approximately 3 5/16" in total length. It has sixteen teeth, but the teeth seem too narrow for the lead screw threads. Is this the correct "thread dial" for my machine or should it be longer so it doesn't "climb" on top of the lead screw? Any suggestions would be greatly appreciated.

Last edited: