- Joined

- Mar 26, 2018

- Messages

- 8,407

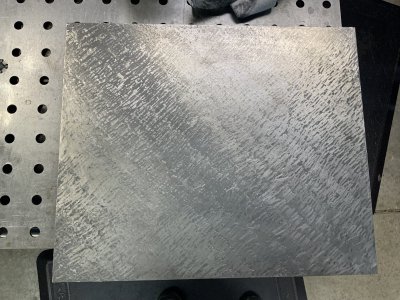

The plate is hinging perfectly. I’ve used .0015 feeler gauges to make sure I’m not high in the center.

After 2 hours of scraping and printing, I feel very close.

The blueing is coming out much better. Maybe a few more dive bombs on the high points.

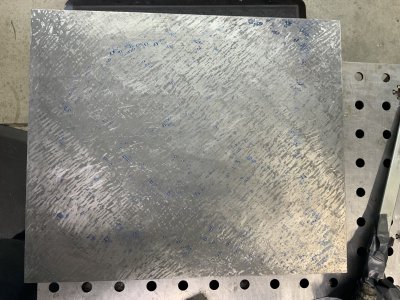

After 2 hours of scraping and printing, I feel very close.

The blueing is coming out much better. Maybe a few more dive bombs on the high points.