It is always a gamble buying asian or Indian vises,or other things. I bought Taiwan 6" Kurt clones in 1980's,and they were o.k.,but things have gone downhill since mainland China got into the act. Indian stuff can be worse.Returning that vise will cost shipping money,too. They are heavy. Even if guaranteed,you'll be responsible for returns.

I only ever bought ENCO vises before I got a real Kurt,so no experience with the Victor offerings. I HAVE been there several times,and saw some pretty crude vises there,though,not the model you are showing,though.

Is there a Northern or a HF near you,where you could just drive to return a vise? You need to go over it with a dial indicator when mounted,to see if the bed is parallel. Also TAKE NOTICE if the FIXED jaw bends back under pressure. See if the vise works smoothly,or if the works have casting sand in them. Some imports are VERY CRUDE inside,and have to be taken apart,cleaned,refined a bit before use.

P.S.: I see you are in N.News. There's a HF in Hampton,and a Northern,too. Go there and look at their vises,try cranking the jaws and see how smooth they feel. At least you can do that in their stores. I think Northern sells that type vise,but haven't been there for a few years. Don't recall seeing them at HF,but I have not been in the market for one,so didn't look carefully for one.

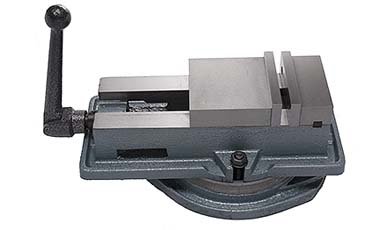

I will say that I have found there swivel base for my Taiwan vises were too thin,and could actually see them lift and flex during cuts in my vertical mill,which is not a real powerful machine. I always look for THICK bases for any vise I buy. That means 3/4" thick around the edges. The center portion is thicker,naturally, it's the edges than can lift up.