- Joined

- Oct 17, 2018

- Messages

- 922

I was thinking I might like to add a VFD to my Rong Fu RF-30 clone machine. Seems it's not as easy or inexpensive as I thought!

I found a guy on YouTube who used this and a motor from a treadmill on his HF wood lathe. 1. Would this particular group of components work for my machine?

Here's the video:

Here's the components: https://www.galco.com/buy/KB-Electr...C6X2WylgJ-xkIMkJ9sYIy1zKocwVgcKxoCjl0QAvD_BwE

I called a local electric motor place and he told me I need to use a 3-phase motor. He also said that mill motors are VERY specific to the machine and that I'd have a hard time finding a 3-phase motor for my particular machine. 2. Anyone know a source for a 3-phase motor for a Rong Fu RF-30 clone?

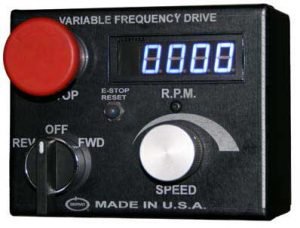

I'd like one that has a dial (rheostat), not buttons, and that has an RPM readout. Like this:

The one above is over $1,000, but it gives you an idea of what I want.

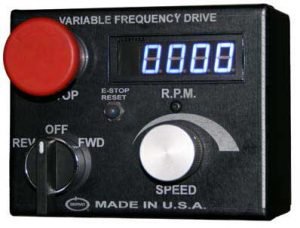

This one was just references on a website with no specific info, but is the size and type I'm looking for, but it needs a tachometer. I wouldn't mind adding one separately.

I've seen some posts about VFD's here and elsewhere, but I must confess I'm a little lost. If someone could point me in the right direction I could learn more and get more info. I'm hoping someone has done this and can show me what they did and where they got the parts.

Here is the info for my motor:

2HP

1.5kW

110/220 Volts (I have it wired for 110)

1720 RPM

23/11.5 Amps

single phase, Class E

I think the frame size is 80, but I'm not sure.

Thanks!

I found a guy on YouTube who used this and a motor from a treadmill on his HF wood lathe. 1. Would this particular group of components work for my machine?

Here's the video:

Here's the components: https://www.galco.com/buy/KB-Electr...C6X2WylgJ-xkIMkJ9sYIy1zKocwVgcKxoCjl0QAvD_BwE

I called a local electric motor place and he told me I need to use a 3-phase motor. He also said that mill motors are VERY specific to the machine and that I'd have a hard time finding a 3-phase motor for my particular machine. 2. Anyone know a source for a 3-phase motor for a Rong Fu RF-30 clone?

I'd like one that has a dial (rheostat), not buttons, and that has an RPM readout. Like this:

The one above is over $1,000, but it gives you an idea of what I want.

This one was just references on a website with no specific info, but is the size and type I'm looking for, but it needs a tachometer. I wouldn't mind adding one separately.

I've seen some posts about VFD's here and elsewhere, but I must confess I'm a little lost. If someone could point me in the right direction I could learn more and get more info. I'm hoping someone has done this and can show me what they did and where they got the parts.

Here is the info for my motor:

2HP

1.5kW

110/220 Volts (I have it wired for 110)

1720 RPM

23/11.5 Amps

single phase, Class E

I think the frame size is 80, but I'm not sure.

Thanks!