- Joined

- Jul 4, 2014

- Messages

- 156

Guys,

I recently made a Dremel tool holder and I tried to use it as a grinder. I see two possibilities. I am not sure which one will be the best.

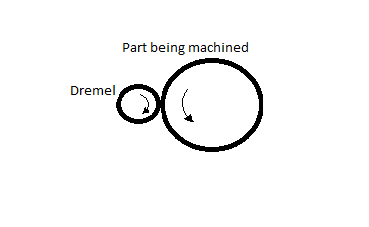

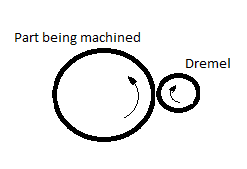

1. Mount the Dremel on the tool post, adjust the compound to the necessary angle and then feed the Dremel tool forward (away from the operator) just as you would if it was a regular cutting tool.

2. Mount the Dremel tool and place it behind the part being machined and bring Dremel towards you (towards operator).

Thanks

Prasad

Wynnewood PA

I recently made a Dremel tool holder and I tried to use it as a grinder. I see two possibilities. I am not sure which one will be the best.

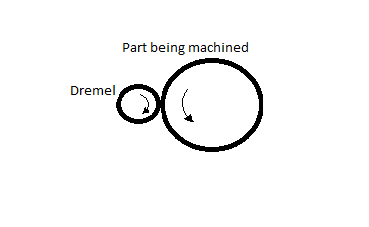

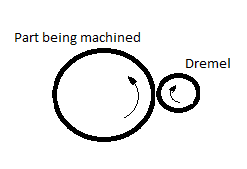

1. Mount the Dremel on the tool post, adjust the compound to the necessary angle and then feed the Dremel tool forward (away from the operator) just as you would if it was a regular cutting tool.

2. Mount the Dremel tool and place it behind the part being machined and bring Dremel towards you (towards operator).

Thanks

Prasad

Wynnewood PA