How did you make the spacers?

I should have shared in the first place but it was dinner time around here.

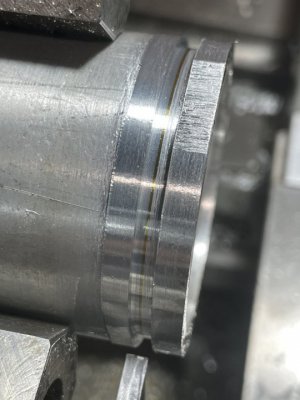

I clamped down squares of brass shim sandwiched between some 1/4” aluminum, drilled and bored a hole in the stack, then moved to the lathe where I turned a quick arbor with a shoulder so the arbor was shorter than the stack, then pressed it together with the tailstock while I turned the OD (using a parting tool because the tailstock pressure pad was too large). Inspired by one of Joe Pie’s videos I remember seeing.

Maybe I should have made more than two, or thought about a reusable jig; at least the arbor is.

Last edited: