- Joined

- Dec 7, 2015

- Messages

- 519

Well it has been a few days... once again... life just seems to be getting in the way. I haven’t really made any new ground since the last post other than to fix this really annoying issue I found.

The quill lock on the tailstock had only about 15 degrees of movement to lock. It seemed really annoying because the lever was always hidden behind the tailstock body itself, and as soon as you start to move the lock lever it almost instantly gets tight.

I thought that if I took 1/3rd rotation off the thread start that it would reposition the end point. That was true as far as completely bottoming the thread on the brass lock itself. Here you can see the 1/3rd rotation, and how the brass nut had moved further after removing the thread:

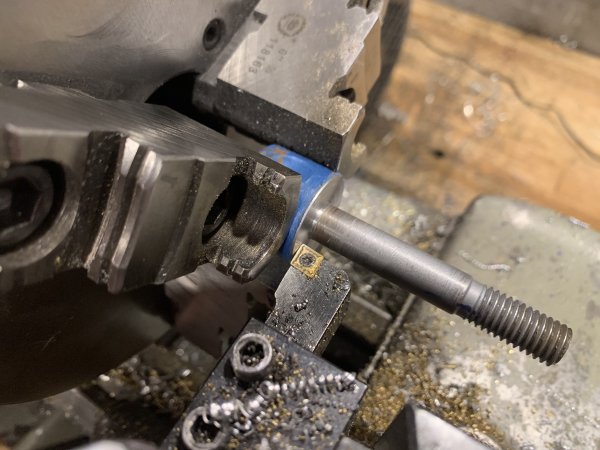

It turned out that that didn’t end up being the limiting factor. Instead the shoulder of the bolt face is what needed turned down:

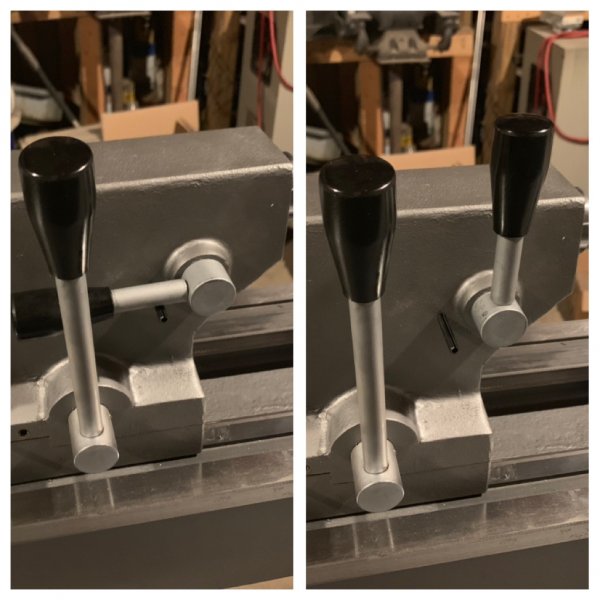

Now I have a much more reasonable travel of the quill lock lever. It doesn’t lock up instantly as soon as you touch it, and it ends in a more appropriate position that just “feels” more useful.

The quill lock on the tailstock had only about 15 degrees of movement to lock. It seemed really annoying because the lever was always hidden behind the tailstock body itself, and as soon as you start to move the lock lever it almost instantly gets tight.

I thought that if I took 1/3rd rotation off the thread start that it would reposition the end point. That was true as far as completely bottoming the thread on the brass lock itself. Here you can see the 1/3rd rotation, and how the brass nut had moved further after removing the thread:

It turned out that that didn’t end up being the limiting factor. Instead the shoulder of the bolt face is what needed turned down:

Now I have a much more reasonable travel of the quill lock lever. It doesn’t lock up instantly as soon as you touch it, and it ends in a more appropriate position that just “feels” more useful.