- Joined

- Dec 7, 2015

- Messages

- 519

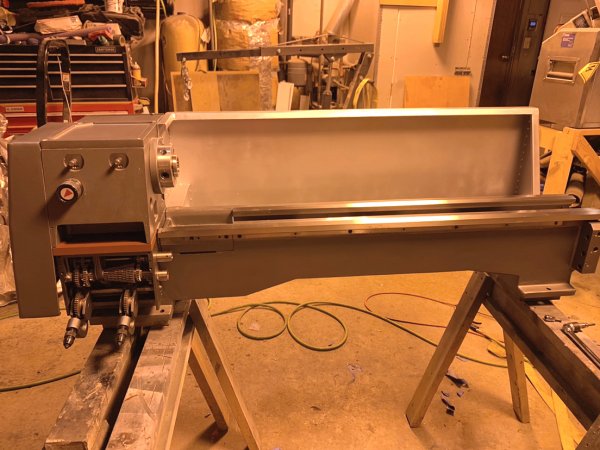

I guess it has been a minute since I've posted. This week I focused mostly on the back splash and the chip pan. I went with a silver/aluminum color for the back splash, and I'm not really 100% sold on it. On top of that, there is never enough natural light in the garage to really gauge it. For the chip pan, I found a brown that feels a bit middle of the road between the aluminum color and a bronze color. I quite like it. I'm not sure if I'll repaint the backsplash in this color or not. I might just rock the tri-tone! haha.

The chip pan got some basic surgery, but man was that difficult! I don't have a mig or tig welder, so I had my buzz box turned all the way down to the lowest amperage. It was still blowing through the thin steel on the pan. I managed to get just enough buggers on there to hold it in place, ground down the crappy welds (I'm actually a pretty good welder, but clearly not on this thin sheet metal!) and filled the remaining holes with JB Weld. I ground down the JB Weld and then smoothed the area with Bondo. In the end you'd have to look pretty close to see the modification, and even then the bed of the lathe is going to be covering this area. I'm really pleased with how it turned out. I also added some custom poor man's embossing. You're welcome, PM. ha!

I'm in the home stretch now. There's still a few small components to paint, and then it's on to machining all of the aluminum pieces for mounting the accessories.

The chip pan got some basic surgery, but man was that difficult! I don't have a mig or tig welder, so I had my buzz box turned all the way down to the lowest amperage. It was still blowing through the thin steel on the pan. I managed to get just enough buggers on there to hold it in place, ground down the crappy welds (I'm actually a pretty good welder, but clearly not on this thin sheet metal!) and filled the remaining holes with JB Weld. I ground down the JB Weld and then smoothed the area with Bondo. In the end you'd have to look pretty close to see the modification, and even then the bed of the lathe is going to be covering this area. I'm really pleased with how it turned out. I also added some custom poor man's embossing. You're welcome, PM. ha!

I'm in the home stretch now. There's still a few small components to paint, and then it's on to machining all of the aluminum pieces for mounting the accessories.