I did say the OP should remove the additional pieces if he thinks it's a problem.

His stand looks like mine with only four adjuster foot mounting points at the ends, not the six points that 1440 lathes usually have, four at the headstock end and two at the tailstock. If that's the case, and you want adjuster feet you would be supporting only at the ends, putting the center panel in compression. Mine is quite thick and with the horizontal bend in the middle I'm pretty sure it's engineered to be plenty rigid for the application. If the lathe is bolted firmly to the bases it will definitely be subjected to any forces transferred from the base. But, the instructions I have say to adjust level with the lathe bed loose. I can't vouch for the OP's stand but when I did have mine supported on the ends with a similar setup it did not throw anything out of adjustment.

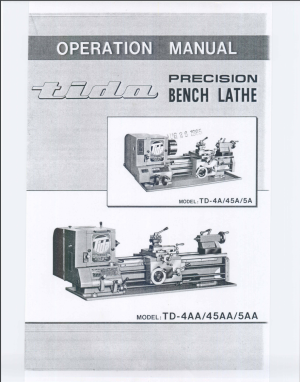

Also, his lathe appears to be a belt drive like mine, not a gear head like the PM 1236 which is definitely about twice the weight. Mine (branded Samson) was made by Tida, the OP's looks very similar to what I have with the lid that opens up to access the belts for speed changes. If that's the case it's a different machine than the PM 1236, or even a geared head Enco 12x36.

The Tida manual is available in the downloads section of this site for anyone that's a contributing member.

View attachment 478348

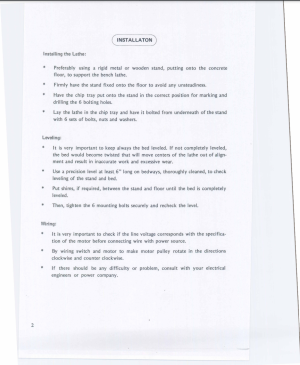

Here's the advice on leveling.

View attachment 478349

I'd definitely recommend the OP download it if he hasn't already, that way he'll know if his is also a rebranded Tida.

I'm certainly not going to question anyone's professional expertise, I currently work as an equipment engineering manager at a small company and sometimes need to consult with our mechanical engineers on structural issues. I'm also not trying to be argumentative, just relying my experience with a very similar machine. I also fretted about supporting the stand only on the ends but ultimately decided it was a non-issue for the level of work I was doing. Eventually, I got the cabinets it's on now so that became a moot point. I would love to have a 1/2" steel plate that would bridge the two cabinets, but since the lathe is supported by the feet cast into the bed it's probably just a desire, not something that will have any effect on accuracy. BTW, my original stands are very stout and are being repurposed as other machine stands.

I also readily admitted there are many others on here who know more than I know about this stuff. I'm basing my comments not only on my experience, but what I've read from folks who post on here that I trust.

Cheers,

John