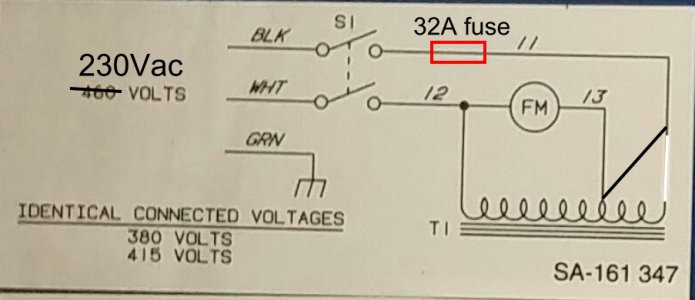

That's what the circuit diagram is showing, 460v across the entire primary with a tap off half way for the fan motor (which I'm assuming is 230vac). It is called an auto transformer and can be done with only one winding needed, and also work the other way round - when you put 230v on as show in my markup you will get 460v at the unused end so make sure you insulate it and don't just leave a wire floating around.

As you haven't increased the wire size you as still limited to the original transformer current limit - which is probably something just above the 33A quoted supply requirement, but how much above is unknown unless you can find some actual markings on the transformer.