@FliesLikeABrick - Are the panels a sub-feed from somewhere else, or are they a primary panel from a service feed from the meter base? If a sub-fed panel, the neutrals and grounds should have been bonded in the primary panel, and NOT in the sub-panel. Cannot have two (or more) ground/neutral bonds. Also, I see a lack of insulating bushings on the conduit fittings where the wires enter the various components, especially the VFD box. Nice installation.

Thanks for your observations/feedback

These are subpanels fed from a main panel within the same structure; neutral is bonded to ground only in the main panel. The bonding screw in the subpanel was removed (or not installed in the first place, I can't remember if it was in a baggie of accessories); and a separate ground bar was ordered and installed in the subpanels.

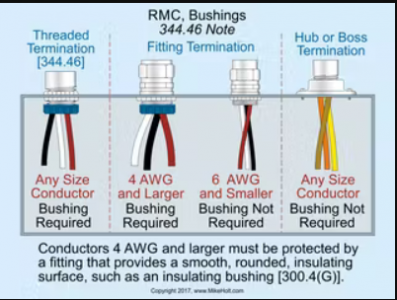

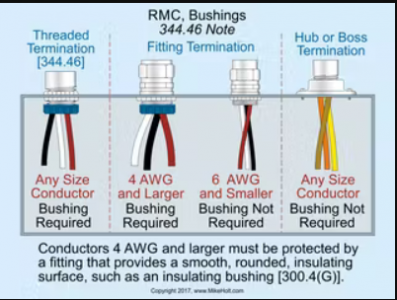

Code specifies bushings are mandatory for 4awg-or-larger conductors, with the consensus being that this is to protect the conductors' own weight from abrading the insulation on a hard edge during installation and over time. This installation is not using any 4awg+ conductors except the SER cable which has the outer jacket and is not in conduit or conduit fittings subject to pulling/scuffing forces. The other situation in which they are required is for threaded RMC conduit itself (due to cut and/or partial threads being exposed), regardless of conductor size:

That all said, of course they can (and should be used) proactively beyond what code actually requires. I did use them anywhere I used 1" or larger conduit, and anywhere that wire pulls could be going over a hard corner on a fitting.

All of the box-to-box or box-to-wireway connections are made with chase nipples that offer similar protection

The VFD box is not covered by the code requirements for bushings because it is a non-hardwired appliance. That said, the cabling coming in is rubber-jacketed in a compression fitting instead of terminating in EMT or RMC in a manner that exposes a sharp edge (that individual conductors may get dragged over). Even if this SO cord was exiting threaded RMC, the outer jacket of the SO cord should provide the necessary protection (akin to a throat protector being used inside RMC instead of a threaded bushing) since the conductor's insulation is the interior of the two layers of insulation and it is not a conduit fitting. On top of all that, the terminal strip is REALLY close to the knockouts in the VFD, it was hard enough to get the wiring routed with proper termination, let alone sneak a bushing in there too

Thank you for your comments - they keep me on my toes and encourage me to double- and triple-check my understanding

I'm confusing separate receptacles from when you split a receptacle (module) into two separate outlets each on a different circuit. I've used MWBC's but prefer isolated breakers to reduce what does get shut off by an overload on one circuit.

I'm confusing separate receptacles from when you split a receptacle (module) into two separate outlets each on a different circuit. I've used MWBC's but prefer isolated breakers to reduce what does get shut off by an overload on one circuit.