- Joined

- Oct 18, 2016

- Messages

- 2,872

I am using olive oil , is there a non-toxic tapping lube or paste?

Thanks

C

This might be better. Haven't tried it yet, but planning on it.

I am using olive oil , is there a non-toxic tapping lube or paste?

Thanks

C

Thanks, gonna try Tapmagic Pro Tapsmells great, but I'd be worried about flys, mice and rats.....

-brino

Thanks, will try a #19, and try to tap with oil( all I have at this point)

C

Hi everyone,

Need some guidance with SS 304 hex head bolt that I drilled 1.25” with a #20 hss 135 point drill.

Tap worked fine in a steel bolt, but can’t get it started in the SS, even with a chamfer?

Brand new tap, HSS

ANY ADVICE IS MUCH APPRECIATED

C

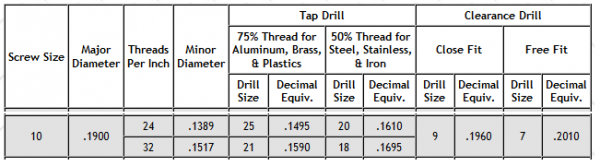

Thanks , that is the exact chart I am using.I like this thread chart.

https://littlemachineshop.com/reference/tapdrill.php

It's easy to find the drill for either 50% or 75% threads, depending on material, application, , etc.

for #10-24 it shows:

View attachment 288484

-brino